How to Identify an Aluminum Profile?

How to Identify an Aluminum Profile

Outline:

Introduction

1. Importance of identifying aluminum extrusion profiles

2. How aluminum profiles impact your projects

What Are Aluminum Extrusion Profiles?

1. Definition of extruded aluminum profiles

2. The extrusion process and why it's important

Different Types of Aluminum Profiles

1. Common aluminum profiles (rectangular, round, square, etc.)

2. Custom aluminum profiles: when and why to use them

3. Industry applications of various profiles

Key Characteristics to Identify Aluminum Profiles

1. Material properties: strength, lightweight, corrosion resistance

2. Surface finishes: anodized, powder-coated, mill finish

3. Identifying profiles based on thickness, strength, and appearance

Identifying Aluminum Profiles Based on Industry Application

1. Construction: window frames, doors, curtain walls, structural components

2. Automotive: vehicle frames, trims, and lightweight parts

3. Industrial and machinery: conveyor systems, support structures

4. Aerospace and transportation: lightweight, high-strength parts

Recognizing Aluminum Profiles by Alloy

1. Common alloys in profiles: 6061 vs. 6063

2. Why alloy selection matters: strength, durability, finish

Choosing the Right Aluminum Profile for Your Project

1. Step-by-step guide to identifying the right profile

2. Understanding load requirements, size, and surface finish

3. Working with your aluminum profile supplier or manufacturer

Why Working with a Trusted Aluminum Profile Supplier is Crucial

1. The importance of verifying your supplier’s reputation

2. Key traits of a reliable extruded aluminum profiles supplier

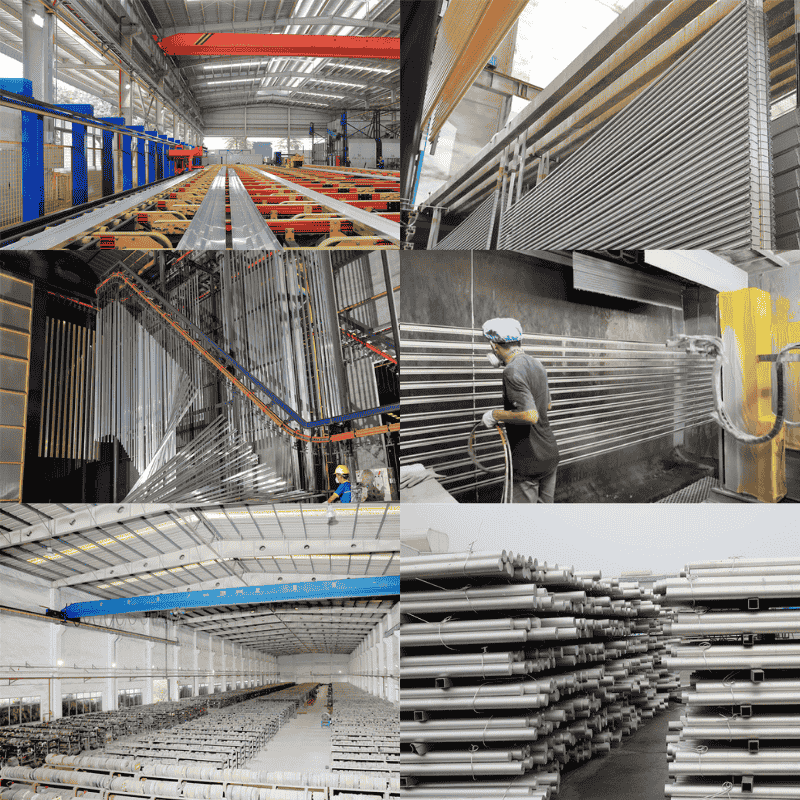

Why Aluinno Aluminum Company is the Best Choice

1. Overview of Aluinno Aluminum's offerings

2. Custom and standard profiles for various industries

3. Trusted supplier and manufacturer with years of expertise

Conclusion

1. Recap of how to identify and choose the right aluminum profile

2. Call to action: Contact Aluinno Aluminum Company for expert assistance

Introduction

Aluminum profiles are everywhere. They frame the windows of your home, form the structure of your car, and provide support in countless industrial applications. But how do you know which aluminum extrusion profiles are right for your project? Identifying the correct aluminum profile can make the difference between a successful project and one that falls short.

Understanding what to look for when identifying an aluminum profile—whether it’s for construction, automotive, or industrial use—can save time, reduce costs, and improve the quality of your end product. This guide will walk you through how to identify aluminum profiles, explain the key characteristics to look for, and show you how to choose the right extruded aluminum profiles for your needs.

What Are Aluminum Extrusion Profiles?

To properly identify an aluminum profile, it’s important to understand what it is and how it’s made. Aluminum extrusion profiles are created through a process called extrusion, where heated aluminum is forced through a die to form a specific shape. These shapes can range from simple squares and rectangles to more complex custom designs.

This process results in profiles that are lightweight, strong, and resistant to corrosion—qualities that make them ideal for a wide range of applications. The extrusion process allows for high precision, ensuring that the profiles can be produced with tight tolerances for both standard and custom shapes.

Different Types of Aluminum Profiles

Aluminum profiles come in various shapes and sizes, each designed for specific applications. Understanding the types of profiles available can help you quickly identify the one you need for your project.

Common Types of Aluminum Profiles

· Rectangular and Square Profiles: These are commonly used in construction and framing. They are ideal for window frames, doorways, and structural components.

· Round Profiles: Often found in pipes, tubes, and railing systems, round profiles provide strength and flexibility.

· L-Shaped and U-Shaped Profiles: These profiles are used for corner supports, brackets, and edge protection in various applications.

· T-Slot Profiles: Popular in industrial machinery, these profiles are known for their modularity and ease of assembly. They allow for quick customization and reconfiguration without the need for welding.

Custom Aluminum Profiles

For unique applications that can’t be met by standard shapes, custom aluminum profiles are the answer. By working with an aluminum profile manufacturer, you can design profiles that meet your exact specifications, from complex geometries to precise tolerances.

Custom profiles are often used in specialized industries like aerospace and automotive manufacturing, where performance and precision are paramount.

Key Characteristics to Identify Aluminum Profiles

When identifying extruded aluminum profiles, you’ll need to evaluate several key characteristics. These include material properties, surface finishes, and the profile’s dimensions. Here’s what to look for:

1. Material Properties

Aluminum’s natural properties make it one of the most versatile materials for extruded profiles. It’s lightweight yet strong, offering an excellent strength-to-weight ratio. Additionally, aluminum is corrosion-resistant, making it suitable for both indoor and outdoor applications.

2. Surface Finishes

The surface finish of an aluminum profile affects both its appearance and performance. Here are the most common finishes:

· Anodized Finish: This process adds a protective oxide layer to the aluminum, enhancing its resistance to corrosion and wear. Anodizing also allows for the addition of color, making it a popular choice in architectural applications.

· Powder Coating: A powder-coated finish offers a durable, aesthetically pleasing surface that resists chipping and fading. It’s perfect for outdoor use or projects where appearance is important.

· Mill Finish: This is the natural finish of aluminum as it comes out of the extrusion process. While it lacks the polish of anodizing or powder coating, it’s often sufficient for internal components or areas where the profile will not be visible.

3. Strength and Thickness

The thickness of an aluminum profile directly impacts its strength. Thicker profiles can handle more load and stress, making them ideal for structural applications, while thinner profiles are better suited for lighter, more aesthetic uses. Identifying the right thickness is crucial for ensuring that your profile can meet the demands of your project.

Identifying Aluminum Profiles Based on Industry Application

One of the most effective ways to identify the right aluminum profile is by understanding its intended application. Each industry has specific needs when it comes to profile shape, strength, and finish.

1. Construction Industry

In construction, aluminum profiles are commonly used for:

· Window and door frames: Aluminum’s corrosion resistance and strength make it ideal for framing systems exposed to the elements.

· Curtain walls: These non-load-bearing walls provide an attractive, weatherproof skin for modern buildings.

· Structural supports: Aluminum profiles are frequently used in bridges, roofs, and other structural applications where strength and light weight are key.

2. Automotive Industry

In automotive manufacturing, reducing weight is critical to improving fuel efficiency. Aluminum profiles are used for:

· Vehicle frames: Extruded aluminum provides the strength needed for car frames while keeping the vehicle lightweight.

· Decorative trims: Aluminum profiles offer sleek, modern lines that are durable and resistant to corrosion.

· Engine components: Lightweight and heat-resistant aluminum profiles are used in various engine and mechanical parts.

3. Industrial and Machinery Applications

In industrial settings, aluminum profiles are essential for:

· Conveyor systems: Lightweight yet strong, aluminum profiles are perfect for building customizable conveyor systems.

· Support structures: From workbenches to storage racks, aluminum profiles provide the support and flexibility needed for industrial machinery and equipment.

4. Aerospace and Transportation

Aluminum’s strength-to-weight ratio makes it the ideal material for:

· Aircraft components: Extruded aluminum profiles are used in fuselage structures, wing supports, and other aircraft parts that require both strength and minimal weight.

· Transportation infrastructure: Aluminum profiles are found in rail systems, bus frames, and shipping containers where durability and light weight are critical.

Recognizing Aluminum Profiles by Alloy

The strength, durability, and appearance of an aluminum profile can also be determined by the alloy used. Two of the most common alloys for extruded aluminum profiles are 6061 and 6063.

1. 6061 Aluminum Alloy

Known for its high strength and excellent corrosion resistance, 6061 aluminum is often used in structural applications that require durability. This alloy is frequently heat-treated to increase its strength, making it suitable for heavy-duty projects like bridges, cranes, and industrial machinery.

2. 6063 Aluminum Alloy

Often referred to as the “architectural alloy,” 6063 aluminum is prized for its smooth surface finish and aesthetic appeal. While not as strong as 6061, it offers excellent corrosion resistance and is easier to extrude into complex shapes, making it ideal for window frames, decorative trims, and other architectural features.

Knowing the alloy composition of your profile helps you ensure that it meets the specific requirements of your project, whether that’s strength, appearance, or corrosion resistance.

Choosing the Right Aluminum Profile for Your Project

Identifying the right aluminum profile requires more than just picking a shape. You’ll need to consider the profile’s strength, dimensions, and surface finish, as well as its intended use. Here’s a step-by-step guide to help you choose the right profile:

1. Evaluate Your Application

Start by understanding where and how the profile will be used. Will it be exposed to weather or extreme temperatures? Does it need to bear heavy loads or serve as a decorative element? Knowing these factors will help you narrow down your options.

2. Consider Load-Bearing Requirements

If your profile will be used in a load-bearing application, you’ll need to select a profile with enough strength to handle the weight. Profiles made from 6061 aluminum are better suited for heavy-duty applications, while 6063 may be a better choice for lighter, aesthetic applications.

3. Match Dimensions to Your Project

Make sure the dimensions of the profile fit the needs of your project. Measure the available space and choose a profile with the appropriate thickness and shape.

4. Choose the Right Surface Finish

If the profile will be visible or exposed to harsh conditions, consider opting for an anodized or powder-coated finish to enhance its durability and appearance.

5. Consult with Your Supplier

When in doubt, consult with an aluminum profile supplier or manufacturer to get expert advice on which profile is best for your needs. Aluinno Aluminum offers personalized guidance to help you select the perfect profile for your project.

Why Working with a Trusted Aluminum Profile Supplier is Crucial

Identifying the right aluminum profile is only half the battle. To ensure you receive high-quality, durable profiles, it’s essential to work with a reputable aluminum profile supplier. Here’s what to look for:

1. Quality Certifications

Choose a supplier that meets industry standards, such as ISO certification. This ensures that the profiles you receive are manufactured to strict quality standards and will perform as expected.

2. Experience and Reputation

Look for suppliers with a proven track record in the industry. Read customer reviews, ask for referrals, and check the supplier’s history of delivering quality products.

3. Custom Profile Capabilities

If your project requires custom profiles, make sure the supplier has the capacity to create them. Aluinno Aluminum specializes in producing both standard and custom profiles tailored to meet specific project requirements.

4. Reliable Delivery

On-time delivery is critical to keeping your project on schedule. Partner with a supplier known for meeting delivery deadlines and offering responsive customer support.

Why Aluinno Aluminum Company is the Best Choice

When it comes to sourcing extruded aluminum profiles, Aluinno Aluminum Company is your go-to partner. Here’s why:

1. Extensive Product Range

Whether you need a standard aluminum profile or a custom aluminum extrusion, Aluinno offers a wide selection of profiles for industries ranging from construction to automotive and aerospace.

2. Commitment to Quality

At Aluinno Aluminum, quality is our top priority. Our profiles are made from high-grade aluminum alloys, ensuring they meet the strictest industry standards for strength and durability.

3. Custom Solutions

Every project is unique, which is why we offer custom profiles designed to meet your exact specifications. Our experienced team will work with you to create a profile that fits your project’s needs.

4. Expert Guidance

Not sure which profile is right for your project? Our knowledgeable team is here to help. We’ll guide you through the selection process, ensuring you choose the right profile for your application.

5. Reliable Delivery

We understand that timely delivery is crucial. With Aluinno Aluminum, you can count on receiving your profiles on schedule, keeping your project on track.

Conclusion

Identifying the right aluminum extrusion profile is essential for ensuring the success of your project. By understanding the different types of profiles, recognizing key characteristics like alloy composition and surface finish, and considering the specific requirements of your application, you can confidently select the best profile for the job.

Working with a trusted extruded aluminum profiles supplier like Aluinno Aluminum Company ensures that you receive high-quality products backed by expert guidance and reliable service.

Ready to find the perfect aluminum extrusion profile for your next project? Contact Aluinno Aluminum Company today for expert advice and a wide range of high-quality extruded aluminum profiles. Whether you need standard profiles or custom designs, Aluinno Aluminum is here to help you achieve your project goals with durable, reliable aluminum solutions.

En

En

Location:

Location: