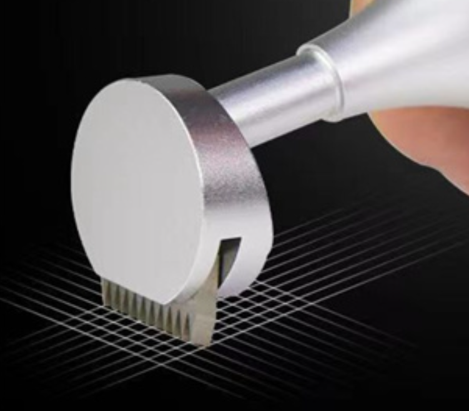

100% test materials to ensure that the ingredients meet customer requirements.

ALUINNO-Submit your request

Please leave your comments or requests below and our team will be in contact shortly.

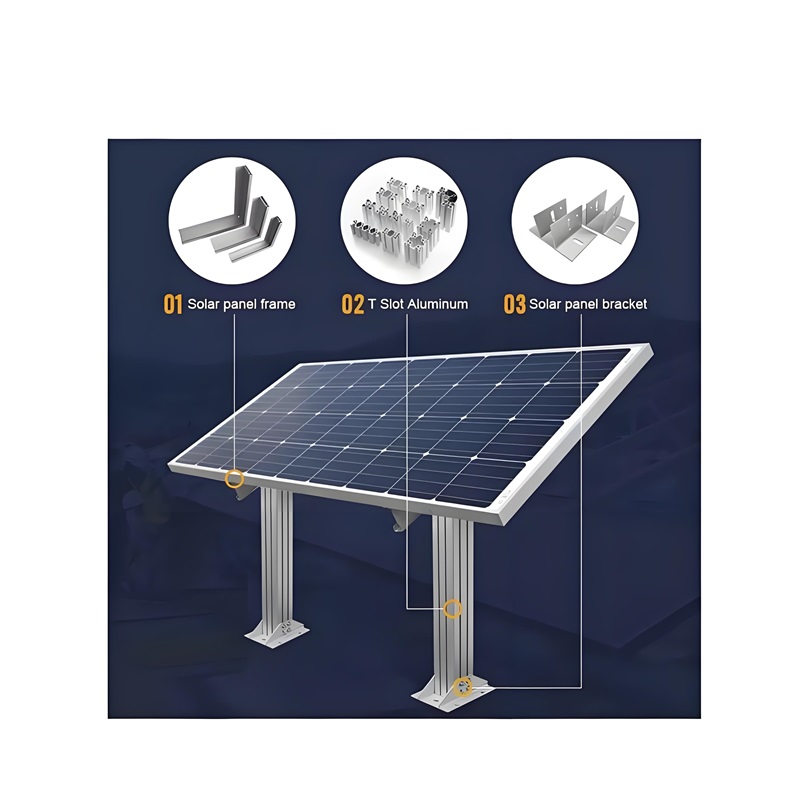

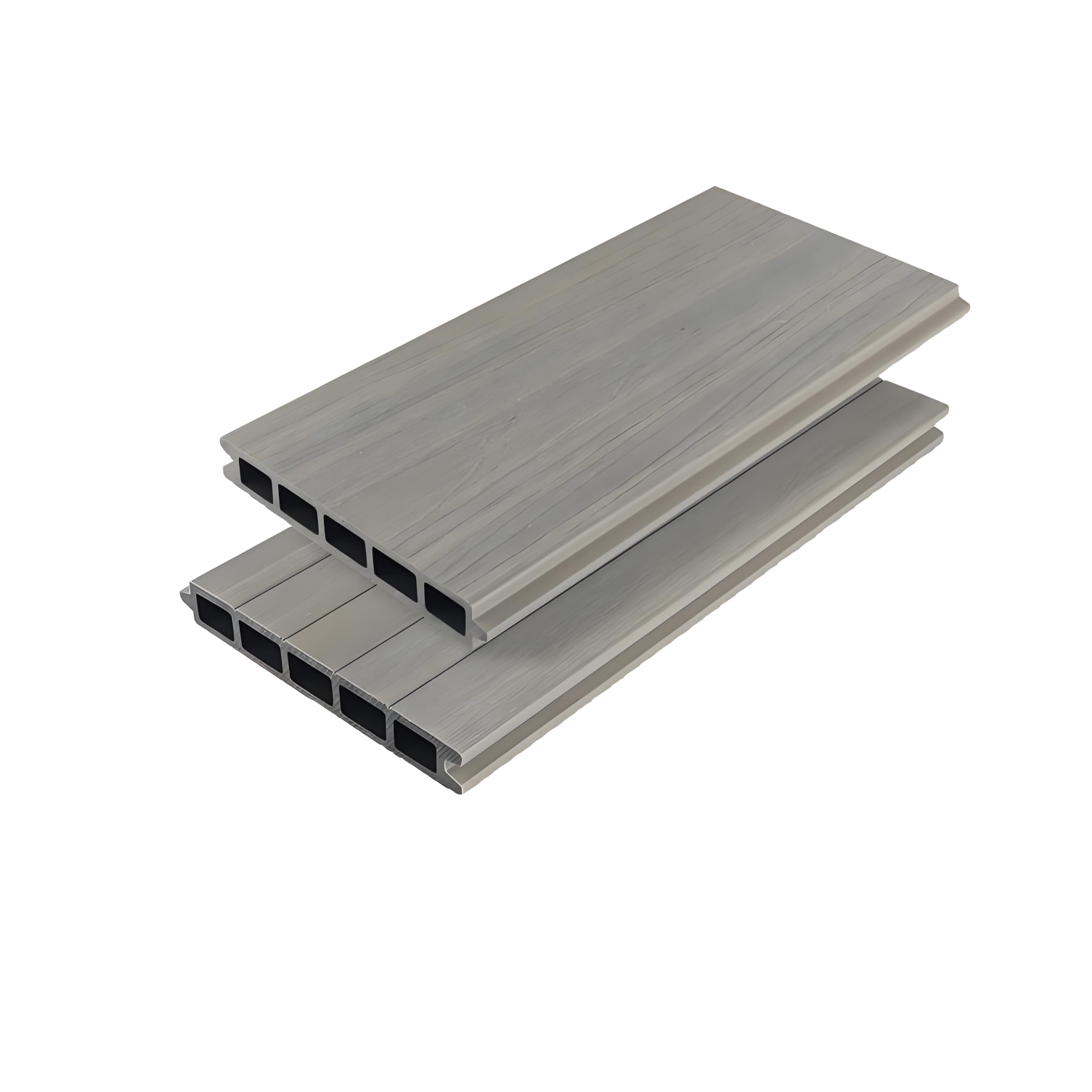

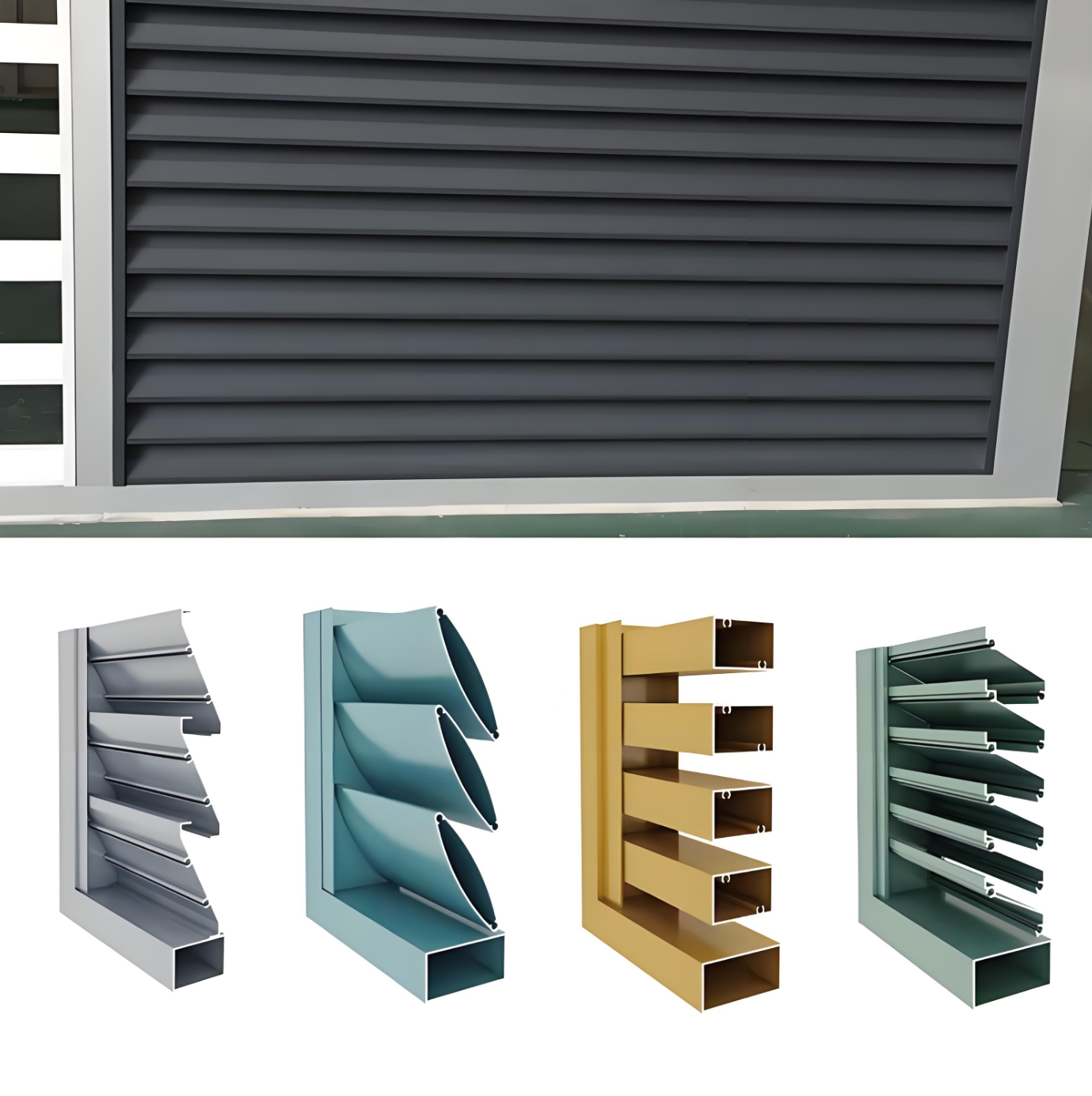

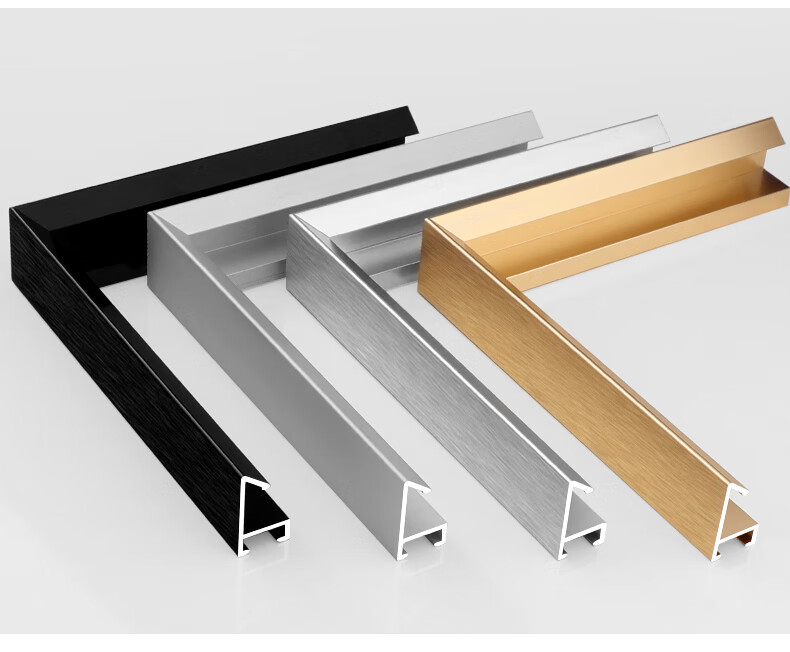

The main products of Guangdong Aluinno Aluminum Co., Ltd. are: aluminum alloy anodized profiles, electrophoretic paint profiles, powder spray profiles, fluorocarbon paint spray profiles, wood grain profiles, wire insulation profiles, cast insulation profiles, and various industrial aluminum alloy profiles; Varieties and specifications have more than ten alloy states, more than 20,000 kinds of specifications and more than 600 kinds of surface colors, including almost all building doors and Windows, curtain walls, decorative aluminum profiles and industrial aluminum profiles of the variety and specifications.

Aluinno Aluminum Plant has established a sound science and technology management system, quality assurance system and ERP modern management engineering system, from the system to ensure that customers with cost competitive advantage of high-quality aluminum profiles.

Step 1: After obtaining the detailed dimensions or drawings of your product, our engineers will discuss and provide cross-sectional drawings for your confirmation.

Step 2: Aluinno will first open the mold for your custom aluminum extrusion, make a sample and send it to you for confirmation.

Step 3: Aluinno will modify the size of the mold until you are satisfied with the sample.

Step 4: Aluinno will examine the raw material using a spectral analyzer and then continue the extrusion production process. Aluinno will keep you posted weekly.

Step 5: Depending on the type of surface treatment you want, Aluinno uses anodizing, electrophoresis, powder spraying, or PVDF.

Step 6: Aluinno will carefully package your product to avoid any damage during transportation.

Step 7: Aluinno will provide a loading report and product test report after shipment and track your shipment weekly until you receive it.

Step 8: Aluinno support team will provide 7X24H VIP service and promote your local market.

The production process of Aluinno Aluminum Plant is complete, including melting casting, extrusion, anodizing coloring, electrophoretic painting, powder spraying, fluorocarbon spraying, wood grain spraying, threading heat insulation, deep processing, finishing and electric polishing.

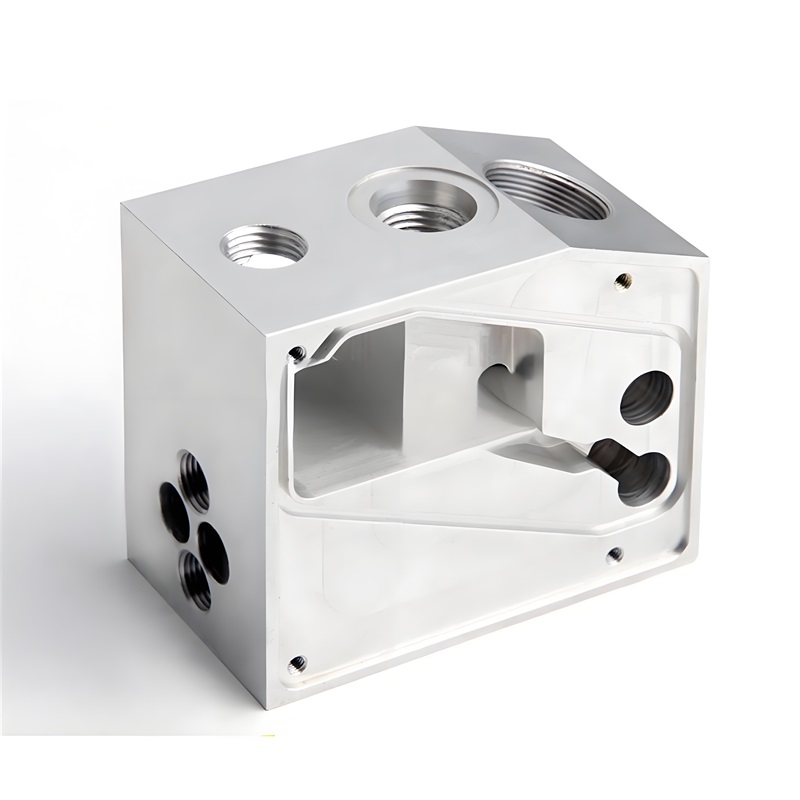

Dear customers, Aluinno can provide OEM and ODM customized aluminum manufacturing services. We have a professional technical team and advanced production equipment, according to your specific needs and design requirements, tailored for you to create high-quality aluminum products. In the customization process, we will strictly control every link to ensure that the product meets your expectations and relevant quality standards. We look forward to working with you to create satisfactory custom results.

Our company has a professional design team and project follow-up specialist to cooperate, the general mold production time is 10~15 days, if there are special circumstances, we can negotiate to deal with the urgent to meet your market demand.

We will provide samples and send them to you for inspection as soon as possible.

For volume production orders, the delivery time is generally 3-4 weeks; We are professional and familiar with various trade methods (EXW, FOB, CIF, DDU, etc.), welcome to consult and compare.

Aluinno Aluminum plant with the United States, Australia manufacturers to establish a technical exchange platform, the introduction of the world's advanced level of production equipment, and has a strong technical force of the team, professional and technical personnel accounted for more than 10% of the number of employees, committed to technological innovation and product development.

The products of Aluinno Aluminum plant are characterized by complete varieties, diverse specifications and rich colors, which can meet the needs of different customers. At the same time, the company focuses on technological innovation and environmental protection and energy saving, providing customers with high-quality aluminum profiles with cost competitive advantages, and has won wide recognition in the market.

Considering the large demand of construction and other industries, Aluinno usually produces 6000 series alloys, but if you need other special alloys, such as 3000 series, 5000 series or 7000 series, we can also produce according to your requirements.

The conventional packaging methods of Aluinno include kraft paper packaging, pearl cotton packaging, shrink film packaging, carton packaging, wooden pallet packaging, etc., can also provide special material packaging customized packaging according to customer requirements, welcome to consult and discuss.

En

En

Location:

Location: