Aluminum Alloy Doors and Windows: Ideal for Buildings and Homes

1. Introduction

In the field of modern architecture and home decoration, doors and windows are not only the openings of a building, but also a key factor affecting the overall beauty, comfort and energy efficiency. Aluminum alloy doors and windows have gradually become a popular choice in the market due to their many advantages. This popular science article will delve into all aspects of aluminum alloy doors and windows, including their material characteristics, advantages, performance indicators, application scenarios, purchase points, maintenance and other knowledge.

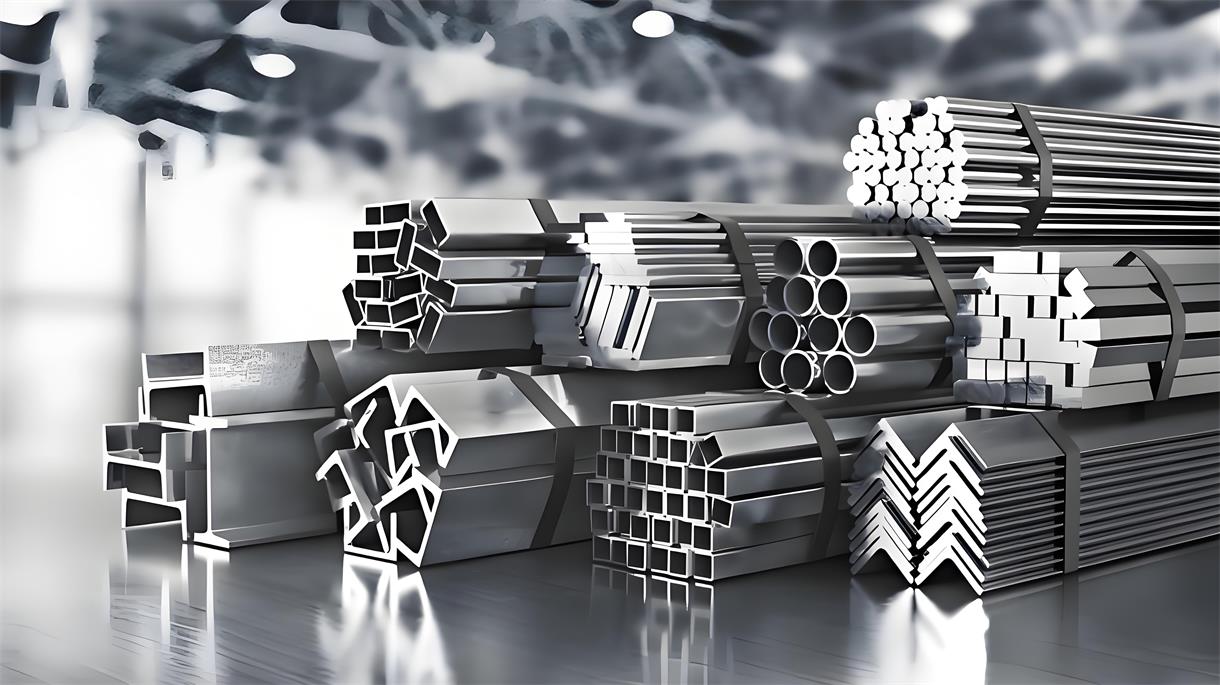

2. Material properties of aluminum alloy doors and windows

(1) Composition of aluminum alloy

Aluminum alloy is an alloy material based on aluminum with other elements (such as magnesium, silicon, copper, etc.) added. The purpose of these added elements is to improve the physical and chemical properties of aluminum, such as increasing strength, hardness, corrosion resistance, etc. For example, the addition of magnesium can significantly improve the strength and toughness of aluminum alloys, making them more suitable for manufacturing door and window structures that can withstand certain pressures and external forces.

| Elements | Composition | Function |

| Al | About 90% - more than 99%, depending on the amount of other elements added | As a basic element, it provides basic metal properties, such as good electrical conductivity, thermal conductivity, etc. |

| Mg | 1% - 5% | Improve strength, hardness and corrosion resistance, and improve welding performance |

| Si | 0.2% - 1.3% | Enhance castability, improve strength and heat resistance |

| Cu | 0.1% - 5% | Increases strength, hardness, and heat resistance, but may reduce corrosion resistance |

| Mn | 0.1% - 1.0% | Improve strength, corrosion resistance, and reduce thermal cracking tendency |

| Zn | 0.1% - 7% | Improve strength, hardness and corrosion resistance |

| Fe | 0.05% - 1.0%(Generally controlled at a low level) | Impurity elements, too high content affects performance |

(2) Manufacturing process

The manufacturing process of aluminum alloy doors and windows involves many complex process links. The first is profile extrusion. The heated aluminum alloy raw material is extruded into a profile of a specific shape through a mold. This process determines the basic shape and structure of the door and window frame. Followed by surface treatment processes, common ones include anodizing, electrophoretic coating, powder spraying,wood grain, etc. Anodizing treatment can form a dense oxide film on the surface of aluminum alloy, which not only enhances corrosion resistance, but also can obtain different color effects through different treatment methods; electrophoretic coating makes the surface coating more uniform, smooth and has Good decoration and weather resistance; powder coating can provide rich color choices, and the coating has strong adhesion and is not easy to fall off.

3. Advantages of aluminum alloy doors and windows

(1) Lightweight and high strength

The density of aluminum alloy doors and windows is relatively small, only about one-third of the density of steel. However, its strength cannot be underestimated and can be close to the strength level of ordinary low carbon steel. This light weight and high strength feature brings many conveniences. During the construction process, the lighter weight makes it easier to transport and install aluminum alloy doors and windows, reducing construction difficulty and labor intensity. At the same time, for the building itself, it reduces the load of doors and windows on the building structure, especially in high-rise buildings. This advantage is particularly important and can improve the overall safety of the building.

(2) Good weather resistance

Aluminum alloy doors and windows have excellent weather resistance and can maintain stable performance under various harsh natural environmental conditions. It has strong resistance to acid and alkali and is not affected by air pollution, acid rain and ozone. Even in coastal areas, where the salt content in the air is high, or in areas with severe industrial pollution, aluminum alloy doors and windows are not easily corroded. In addition, aluminum alloy doors and windows also have good UV resistance. When exposed to sunlight for a long time, the color and gloss of their surfaces can remain unchanged without fading or aging.

(3) Zero formaldehyde environmental protection

As people's awareness of health and environmental protection continues to increase, the environmental protection properties of aluminum alloy doors and windows have become one of their major advantages. Aluminum alloy itself is a non-toxic and non-hazardous material, and does not contain formaldehyde and other volatile organic compounds (VOCs) that are harmful to the human body. In contrast, some wooden doors and windows may release formaldehyde, polluting indoor air quality, especially in newly renovated homes. Therefore, aluminum alloy doors and windows are particularly suitable for use in homes, hospitals, schools and other places with high air quality requirements.

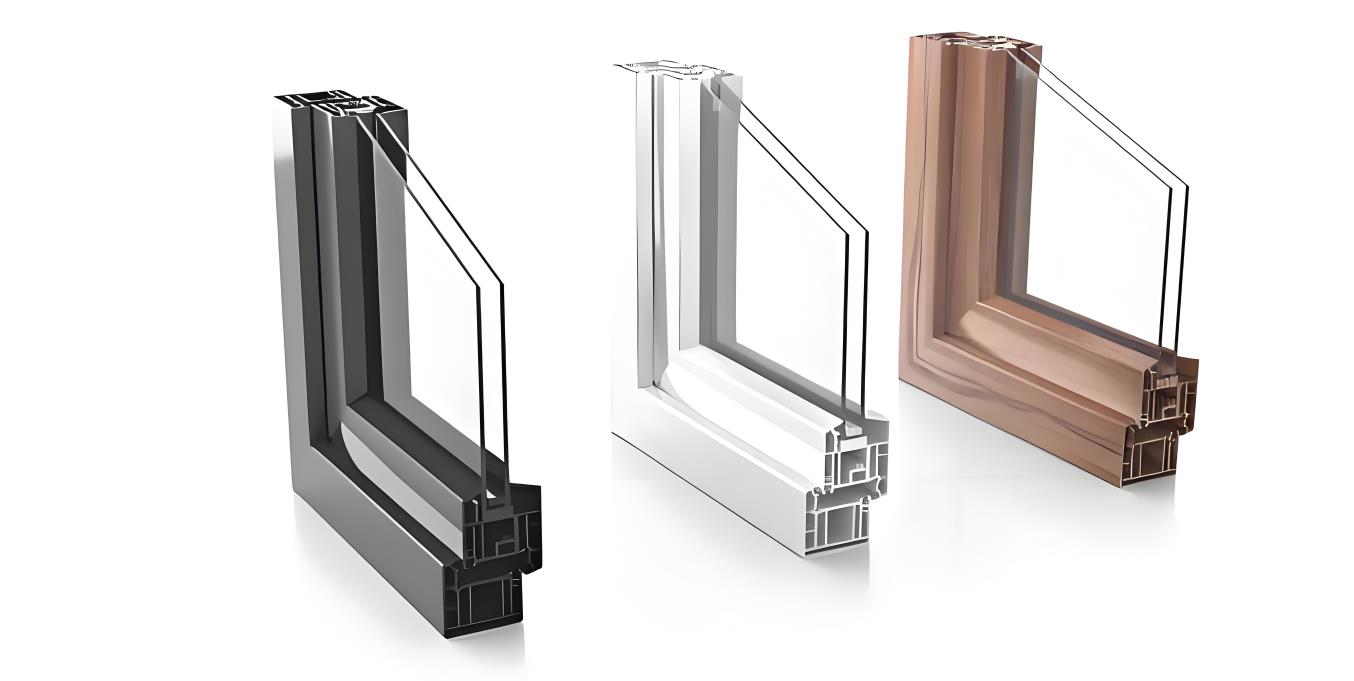

(4) Good decorative effect

After special treatment, the surface of aluminum alloy doors and windows can present a variety of colors and textures, providing a wealth of options for construction and home decoration. Through processes such as anodizing, electrophoretic coating or powder spraying, the surface of doors and windows can be made to show metallic luster, matte effects or simulate special textures such as wood grain and stone grain to meet the needs of different decorative styles. In addition, aluminum alloy doors and windows can also be matched with various special and decorative glasses, such as frosted glass, colored glass, coated glass, etc., to further enhance the decorative effect. Large-size aluminum alloy floor-to-ceiling windows or glass doors can make the indoor space more transparent and bright, while also creating a spacious and modern visual experience; while aluminum alloy doors and windows with decorative glass can add an artistic atmosphere to the interior.

(5) Good sealing performance

Aluminum alloy doors and windows have precise cross-sectional dimensions and high processing precision, which provides the basis for achieving good sealing performance. The fixing groove and the profile are integrally formed, creating favorable conditions for the installation of sealing materials. High-quality sealing strips are installed at the gaps between doors and windows to effectively prevent the penetration of dust, rain, air, etc. Good sealing performance can not only keep the indoor environment clean and dry, but also improve the sound insulation and heat insulation effects of doors and windows. In the cold winter, well-sealed aluminum alloy doors and windows can reduce the loss of indoor heat and reduce heating costs; in the hot summer, they can prevent the intrusion of outdoor heat and reduce the load on the air conditioner, thereby achieving energy saving.

4. Performance indicators of aluminum alloy doors and windows

(1) Strength and stiffness

The strength of aluminum alloy doors and windows refers to their ability to resist damage from external forces. It is usually measured by indicators such as yield strength and tensile strength. In practical applications, doors and windows need to withstand external forces such as wind load, dead weight, and possible impacts. Therefore, sufficient strength is a basic requirement to ensure the safe use of doors and windows. According to different usage scenarios and building codes, the profile thickness and structural design of aluminum alloy doors and windows need to meet corresponding strength standards.

Stiffness refers to the ability of doors and windows to resist deformation when stressed. If the rigidity of doors and windows is insufficient, they will easily deform when subjected to external forces, thus affecting their normal use and sealing performance. In order to ensure the rigidity of doors and windows, in addition to selecting appropriate profile specifications, it is also necessary to reasonably design the frame structure of doors and windows, such as adding reinforcement ribs and other measures.

(2) Sound insulation performance

The sound insulation performance of aluminum alloy doors and windows mainly depends on its sealing performance, the type of glass and the structural design of the doors and windows. The quality of the sealing strip and the tightness of its installation have an important impact on the sound insulation effect. When the doors and windows are closed, the sealing tape can effectively block the propagation of sound.

Glass is another key factor in sound insulation performance. Double-layer insulated glass or multi-layer composite glass has better sound insulation effect than ordinary single-layer glass. Among them, the air layer in the middle of double-layer insulating glass can buffer and absorb sound, while special sound-insulating glass (such as laminated glass, coated glass, etc.) can effectively block sound according to different frequency ranges.

In terms of structural design, the frame structure of doors and windows should try to avoid "bridges" for sound transmission. For example, using a broken bridge aluminum structure can effectively cut off the path of sound propagation through the door and window frames and improve the overall sound insulation performance.

(3) Thermal insulation performance

Thermal insulation properties are critical to a building’s energy efficiency. The thermal insulation performance of aluminum alloy doors and windows is mainly achieved through the thermal insulation design of the profile and the thermal insulation performance of the glass. Thermal broken bridge aluminum profile is a common design to improve the thermal insulation performance. It divides the aluminum alloy profile into inner and outer parts, which are connected by thermal insulation materials (such as nylon strips) in the middle to prevent heat from being conducted through the profile.

The thermal insulation properties of glass cannot be ignored. Low-emissivity (LOW-E) glass is a glass material with good thermal insulation properties. It can reflect infrared radiation and reduce the exchange of indoor and outdoor heat. When choosing aluminum alloy doors and windows, the use of double-layer hollow LOW-E glass can significantly improve the thermal insulation performance of doors and windows and reduce the energy consumption of the building, especially in terms of winter heating in cold areas and summer cooling in hot areas.

(4) Watertightness

Watertightness refers to the ability of doors and windows to prevent rainwater from penetrating into the room when it is attacked by rainwater. The watertightness of aluminum alloy doors and windows mainly relies on its precise manufacturing process and sealing design. The sealing between the frame and the glass of doors and windows, and between the frame and the wall must be tight to prevent rainwater from leaking.

In terms of design, doors and windows are usually equipped with drainage systems, such as drainage holes, drainage channels, etc., to drain rainwater that may accumulate in the door and window frames in a timely manner. Good water tightness can ensure that there will be no indoor leakage under heavy rain conditions, protecting indoor decoration and items from rain damage.

5. Application scenarios of aluminum alloy doors and windows

(1) Residence

In the living room of a house, aluminum alloy floor-to-ceiling windows are a common choice. It can provide a broad view, bring the outdoor natural landscape indoors, and make the living room full of vitality and beauty. At the same time, the large-size design of floor-to-ceiling windows can increase the indoor lighting area and make the living room brighter. Moreover, the good sound insulation performance of aluminum alloy doors and windows can effectively block external noise and create a quiet and comfortable leisure and entertainment space for the family.

There are also many benefits to using aluminum alloy doors and windows for bedroom windows. For example, the design of casement windows or inward-opening inverted windows can flexibly adjust the ventilation volume according to needs while ensuring indoor safety. In coastal areas or places with high humidity, the corrosion resistance and moisture-proof properties of aluminum alloy doors and windows can protect the dryness and comfort of the bedroom interior, helping to improve sleep quality.

Aluminum alloy glass doors are usually used to separate the kitchen from the dining room or living room. This kind of door can not only prevent the spread of oil smoke and odor in the kitchen to other rooms, but also keep the interior of the kitchen brightly lit. The aluminum alloy material is easy to clean. Just wipe it with a damp cloth to remove oil stains, making daily cleaning and maintenance convenient.

(2) Commercial buildings

The exterior facades of office buildings often use aluminum alloy curtain wall doors and windows. This kind of doors and windows not only have good lighting effects, making the interior of the office building full of light, but also can improve the overall aesthetics of the building and show a high-end and elegant modern commercial architectural style. From the perspective of internal office space, aluminum alloy partition doors and windows can flexibly divide office areas, ensuring the privacy of each office area without affecting the overall transparency and lighting effect. In addition, the durability and low maintenance costs of aluminum alloy doors and windows also meet the needs of commercial office environments.

Large aluminum alloy automatic sliding doors or revolving doors are generally installed at the entrance of shopping malls. These doors can meet the needs of large numbers of people entering and exiting shopping malls, and have good safety and stability. Aluminum alloy glass doors and windows are also a common choice for store separation inside shopping malls, which allow customers to clearly see the products in the store while creating an independent commercial space atmosphere.

(3) Public buildings

In schools, most classroom windows are made of aluminum alloy casement windows. This kind of window can provide good lighting and ventilation conditions, which is beneficial to students' learning and health. At the same time, the durability of aluminum alloy doors and windows can withstand various collisions and frictions in students' daily use. Aluminum alloy doors and windows are also widely used in school libraries, gymnasiums and other buildings. For example, in order to meet the dual needs of lighting and sound insulation, libraries will install special aluminum alloy double-layer hollow glass doors and windows; in order to facilitate ventilation and ensure personnel safety, gymnasiums Aluminum alloy sliding doors will be used.

Hospitals are places with high environmental hygiene and functional requirements, and aluminum alloy doors and windows are also widely used in hospitals. The windows in the ward are made of aluminum alloy casement windows, which are easy to clean and disinfect and comply with the hospital's hygienic requirements. The opening angle can be flexibly adjusted as needed to ensure the freshness of the air in the ward, which is beneficial to the patient's recovery. In special areas such as hospital operating rooms and examination rooms, aluminum alloy doors and windows with good airtightness can effectively prevent bacteria and dust from entering, creating a clean environment for medical operations.

6. Key points for purchasing aluminum alloy doors and windows

(1) Choose regular manufacturers

Aluminum alloy door and window products produced by regular manufacturers are more guaranteed in terms of quality, workmanship and after-sales service. When purchasing, you can check the manufacturer's production qualifications, industry reputation, product certification and other information. Doors and windows produced by regular manufacturers will have signs on obvious parts, and there will also be words and signs such as "moisture-proof" and "handle with care" on the packaging boxes.

You can judge the manufacturer's production strength and product quality reliability by visiting the manufacturer's production workshop or viewing the manufacturer's promotional materials to understand its production equipment, process flow and quality control system.

(2) Profile quality

Profile thickness is one of the important indicators to measure the quality of aluminum alloy doors and windows. The profile thickness should not be less than 1.8mm for external windows and 1.4mm for internal windows. Thicker profiles perform better in terms of strength and durability, and can withstand greater pressure and external impact.

The thickness of the oxide film is also a factor that needs attention. Aluminum alloy doors and windows with an oxide film thickness of no less than 10 microns have better corrosion resistance and oxidation resistance. In addition, performance indicators such as pressure-bearing capacity and water tightness of the profile must also be considered. Relevant information can be obtained by checking the product's test report or consulting the manufacturer.

(3) Surface treatment

The surface treatment of aluminum alloy doors and windows directly affects their appearance, durability and decorative effect. The surface of doors and windows after anodizing treatment has good corrosion resistance and hardness, and the color is uniform and long-lasting; the doors and windows of electrophoretic coating have smooth surface, bright color and good decorative properties; the powder-coated doors and windows can provide rich color choices. And the coating has strong adhesion.

When purchasing, you can observe the texture of the door and window surfaces. There should be no dents or bulges. The paint surface should be corrosion-resistant, wear-resistant, high-gloss, and have no obvious color differences and defects.

(4) Glass selection

Glass is an important component of aluminum alloy doors and windows and has an important impact on the performance of doors and windows. Double-layer insulating glass is a more common choice, which has better sound insulation and heat insulation effects. If you have higher requirements for sound insulation or thermal insulation performance, you can consider choosing double-layer hollow LOW-E glass or multi-layer composite glass.

When selecting glass, pay attention to the flatness and firmness of the glass. The installation should be smooth and firm without looseness. At the same time, attention should also be paid to the safety of the glass, such as whether safety glass materials such as tempered glass are used to prevent injuries to people when the glass breaks.

(5) Hardware accessories

Although hardware accessories account for a small proportion of aluminum alloy doors and windows, they have a vital impact on the normal use and service life of doors and windows. High-quality hardware accessories can ensure that doors and windows can be opened and closed flexibly, smoothly, and have good durability. For example, the quality of hinges, handles, locks and other hardware is directly related to the experience of using doors and windows.

When purchasing, pay attention to the material, craftsmanship and brand of hardware accessories. Generally speaking, stainless steel hardware accessories have better corrosion resistance and strength; at the same time, hardware accessories from well-known brands are more guaranteed in terms of quality and after-sales service. For some special opening methods (such as inside opening and inside pouring), it is necessary to ensure the matching and reliability of hardware accessories.

7. Maintenance of aluminum alloy doors and windows

(1) Cleaning

Clean doors and windows regularly, wipe with mild detergent and soft cloth, and avoid strong acid, strong alkali or abrasive detergents. Use glass cleaner to clean glass, and pay attention to cleaning gaps and drainage holes.

(2) Inspection and maintenance

Check hardware accessories regularly, and repair or replace them in time if they are loose, rusty or damaged.

Check whether the sealing strips are aging, deformed or falling off, and replace them in time. Check the sealing between the door and window frames and the wall, and repair them in time if there are leaks.

Lubricate active parts such as window sashes and door sashes regularly to ensure flexible opening and closing.

8. Conclusion

Aluminum alloy doors and windows have become an important part of modern architecture and home decoration due to their material characteristics, advantages, performance indicators and wide application scenarios. Proper maintenance can extend their service life. With the development of technology, aluminum alloy doors and windows will continue to innovate and progress to provide better solutions for building spaces.

En

En

Location:

Location: