Unveiling the Standards of Aluminum Profiles: A Comprehensive Guide

Outline

Introduction

In the grand tapestry of modern industrial development, aluminum profiles stand out as an indispensable and transformative element. Their influence permeates various sectors, from the towering skyscrapers that shape city skylines to the high - speed aircraft soaring through the clouds.

The construction industry leans on aluminum profiles for their corrosion - resistant and lightweight qualities, enabling the creation of innovative and durable structures. In the automotive realm, these profiles play a pivotal role in enhancing fuel efficiency by reducing vehicle weight. Meanwhile, the aerospace industry relies on their high strength - to - weight ratio for building safe and efficient aircraft.

However, with such widespread usage, a clear understanding of aluminum profile standards is not just beneficial; it's essential. This knowledge ensures product quality, safety, and seamless integration across diverse applications, which is precisely what this comprehensive guide aims to unveil.What Are Aluminum Extrusion Profiles?

Defining Extruded Aluminum Profiles

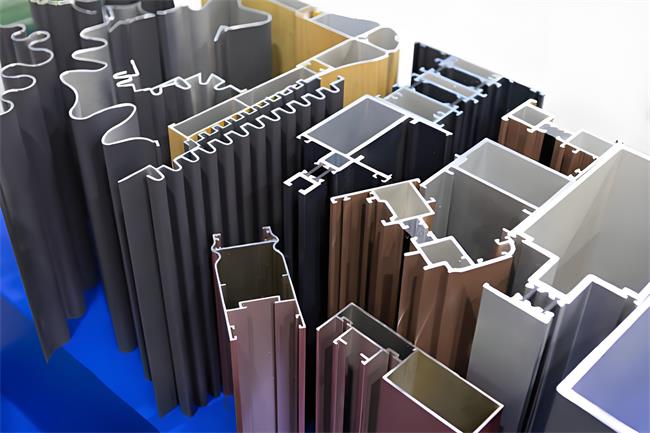

Extruded aluminum profiles are the result of a fascinating manufacturing process where aluminum, in a semi - molten state, is forced through a die to create a specific cross - sectional shape. This shape can be as simple as a square or as intricate as a multi - chambered design for a high - performance application. The extrusion process imparts unique mechanical properties to the aluminum, enhancing its strength and durability while maintaining its inherent lightweight nature.

The Extrusion Process

The journey of an aluminum extrusion profile begins with the selection of the appropriate aluminum alloy. Different alloys are chosen based on the final product's requirements, with factors such as strength, formability, and corrosion resistance in mind. Once the alloy is selected, it is melted and cast into billets. These billets are then heated to a precise temperature that allows for optimal plasticity.

In the extrusion press, a powerful ram pushes the heated billet through the die. The die's shape is replicated in the extruded aluminum, creating a continuous profile. After extrusion, the profile is often quenched to lock in its mechanical properties. Straightening processes are then employed to correct any deviations in shape or alignment, ensuring the profile meets the required dimensional accuracy.

The Different Types of Aluminum Profiles

Standard Profiles

Standard aluminum profiles are the workhorses of many industries. Square profiles, for example, are renowned for their balanced strength distribution. In construction, they are used to build sturdy frames for buildings and furniture. Their simplicity makes them easy to work with, and they can be easily joined together using various fastening methods.

Round profiles, or tubes, are favored for their ability to withstand external forces from all directions. In applications like handrails and structural columns, their circular cross - section provides excellent load - bearing capabilities while remaining lightweight.

Rectangular profiles are highly versatile. Their flat sides make them ideal for applications where easy attachment of other components is required. In the construction of industrial shelving systems, rectangular profiles are commonly used to create strong and stable structures.

L - shaped and U - shaped profiles serve specific purposes. L - shaped profiles are often used as corner connectors, providing additional support at joints. U - shaped profiles can be used for edge protection or as channels for wiring and piping.

| Product Type | Tensile Strength (MPa) | Yield Strength (MPa) | Load-Bearing Capacity (Relative) |

| Aluminum Alloy Round Tube | High (varies by alloy) | Moderate | Moderate to High (depends on OD and WT) |

| Aluminum Alloy Square Tube | High (varies by alloy) | High | High (due to shape and wall thickness options) |

| L-Shaped Aluminum Profile | Moderate | Low to Moderate | Low to Moderate (depends on leg length and thickness) |

| U-Shaped Aluminum Profile | Moderate | Low to Moderate | Moderate (good for light to medium loads) |

Custom Profiles

Custom aluminum profiles are the solution for projects with unique requirements. In the aerospace industry, where every component must be optimized for weight and performance, custom profiles are designed to fit precisely into complex aircraft structures. These profiles can be engineered to have specific wall thicknesses, internal structures, and surface finishes to meet the exacting standards of the aerospace sector.

In the automotive industry, custom profiles are used to create components that enhance vehicle safety, performance, and aesthetics. For example, a custom - designed aluminum profile for a high - end sports car might be crafted to improve aerodynamics while providing structural integrity.

Modular Profiles

Modular profiles, such as T - slot profiles, have revolutionized industrial assembly processes. Their unique design allows for quick and easy disassembly and reassembly without the need for complex welding or specialized tools. In manufacturing plants, T - slot profiles are used to build flexible workstations that can be reconfigured as production needs change. They are also commonly used in conveyor systems, where the ability to add or remove components easily is essential for adapting to different production lines.

Aluminum Profiles by Industry Use

Construction

In construction, aluminum profiles are used in a multitude of ways. Aluminum casement windows are a prime example of their application. The corrosion - resistance of aluminum ensures that these windows can withstand harsh weather conditions, from coastal salt - laden air to heavy rainfall. Aluminum profiles are also integral to the construction of curtain walls, which not only add a modern aesthetic to buildings but also provide insulation and protection from the elements.

For roofing and structural supports, aluminum's high strength - to - weight ratio makes it an excellent choice. It can reduce the overall weight of a building while maintaining the necessary structural integrity, especially in large - scale commercial construction projects.

Automotive

The automotive industry has embraced aluminum profiles to achieve significant weight reduction without sacrificing safety. Aluminum body frames are becoming increasingly common, as they can improve fuel efficiency and vehicle handling. Exterior trims and components made from aluminum profiles offer durability and a sleek appearance.

In the engine compartment, aluminum profiles are used to reduce the weight of components such as engine mounts and intake manifolds. This weight reduction directly translates into improved performance and fuel economy.

Aerospace

In aerospace, aluminum profiles are subject to some of the most stringent standards. Aircraft frames made from extruded aluminum profiles must be able to withstand extreme forces during flight while being as lightweight as possible. Interior structures, like seat frames and overhead storage bins, are also made from aluminum profiles to minimize the overall weight of the aircraft.

Wing components, such as spars and ribs, are critical for aircraft performance. Aluminum's high strength - to - weight ratio makes it the material of choice for these components, as they need to support the wing's structure and aerodynamic loads.

Industrial Applications

In industrial settings, aluminum profiles are used to build machinery frames, support systems, and conveyor structures. Their lightweight nature makes it easier to move and reposition equipment, while their strength ensures the stability of heavy machinery. T - slot aluminum profiles are particularly popular in conveyor systems, as they allow for easy modification and addition of components to adapt to different production requirements.

Marine Industry

The marine industry relies on aluminum profiles for their exceptional corrosion resistance in saltwater environments. Boat hulls and decks made from aluminum profiles are lightweight, which improves fuel efficiency and speed. Aluminum is also used to construct docks and piers, as it can withstand the constant exposure to water, salt, and harsh weather conditions without corroding.

Understanding Surface Finishes for Aluminum Profiles

Anodizing

Anodizing is an electrochemical process that thickens the natural oxide layer on the surface of aluminum. This process significantly enhances the material's corrosion resistance. Anodized aluminum can also be colored, offering a wide range of aesthetic options. In architectural applications, anodized aluminum is often used for its durability and the ability to match the building's design scheme.

Powder Coating

Powder coating involves applying a dry powder to the surface of the aluminum profile, which is then cured under heat. This creates a thick, durable finish that provides excellent protection against abrasion, corrosion, and weathering. Powder - coated aluminum profiles are commonly used in outdoor furniture, automotive parts, and industrial equipment due to their long - lasting performance.

Mill Finish

The mill finish is the natural, untreated surface of aluminum as it comes out of the extrusion process. While it lacks the protective properties of anodizing or powder coating, it has a unique, raw aesthetic appeal. Mill - finish aluminum is suitable for indoor applications where the profile will not be exposed to harsh conditions and where a more natural look is desired.

Standard vs. Custom Aluminum Profiles

When to Choose Standard Profiles

Standard profiles are the most cost - effective option for many projects. If your application does not require any special dimensions or features, standard profiles are readily available and can be quickly incorporated into your project. For example, in a basic DIY furniture project or a simple industrial storage rack, standard profiles can meet the requirements without the need for additional customization.

When to Opt for Custom Profiles

Custom profiles are necessary when your project has specific requirements that cannot be met by standard profiles. In high - tech industries like electronics manufacturing, where components need to fit into very precise spaces, custom profiles are designed to exact specifications. In architectural projects with unique design concepts, custom profiles can be created to bring the vision to life.

Benefits of Custom Profiles

Custom design profiles offer unparalleled flexibility. They can be designed with exact dimensions, ensuring a perfect fit for your application. Custom profiles also allow for the integration of unique features, such as internal channels for wiring or specific surface textures for better grip. This level of customization can lead to improved performance and functionality in your project.

Choosing the Right Aluminum Profile for Your Project

Key Factors to Consider

Strength is a fundamental factor. For load - bearing applications, you need to select a profile with sufficient strength to support the intended weight. Size and shape must be carefully evaluated to ensure that the profile fits into your project's design. If the profile will be exposed to moisture, chemicals, or saltwater, corrosion resistance should be a top priority. The surface finish should be chosen based on the desired appearance and the level of protection required.

Industry - specific Needs

Each industry has its own set of unique requirements. In the construction industry, building codes and regulations often dictate the minimum strength and fire - resistance standards for aluminum profiles. The automotive industry focuses on crash - worthiness and the ability to withstand high - speed impacts. The aerospace industry demands the highest levels of quality control and material consistency.

Working with a Trusted Supplier

A reliable aluminum profile supplier is your partner in ensuring the success of your project. A trusted supplier can provide expert advice on choosing the right profile for your specific needs. They can also ensure that the profiles meet the required standards, whether it's national or international quality certifications. Additionally, a good supplier can offer timely delivery and after - sales support, which is crucial for the smooth progress of your project.

Conclusion

In conclusion, the world of aluminum profiles is vast and complex, with a multitude of types, applications, and standards. From the basic standard profiles that serve a wide range of general purposes to the highly specialized custom profiles designed for unique projects, each has its own role to play. Understanding the extrusion process, surface finishes, and industry - specific requirements is essential for making the right choice.

By working with trusted suppliers and keeping abreast of the latest advancements in aluminum profile technology, you can ensure that your projects benefit from the best that this versatile material has to offer. Whether you are a builder constructing a new high - rise, an automotive engineer designing the next generation of vehicles, or an industrial manufacturer creating cutting - edge machinery, the knowledge of aluminum profile standards will guide you towards success.

En

En

Location:

Location: