luminium Heat Sinks: Keeping Things Cool

Outline

Introduction

Significance of heat dissipation in modern tech & industry.

Role of aluminium heat sinks and Aluinno's position.

What Are Aluminium Heat Sinks

Definition: Structure and function.

Working Principle: Conduction, convection, radiation.

The Role of Aluminum Profiles

Significance: Structural support and design optimization.

Types: Industrial and custom profiles.

Extrusion Aluminium Process

Understanding Extrusion: Process details.

Advantages: Cost-effective and customizable.

Custom Aluminum Solutions

Tailoring: For specific industries' needs.

Design Considerations: Load, environment, constraints.

Industrial Applications

Various Industries: Power, automotive, telecom.

Benefits: Corrosion resistance, strength-weight ratio.

aluinno's Expertise

Product Range: Standard and custom.

Quality Assurance: High standards.

Services: Customization and consultation.

Choosing the Right Heat Sink

Factors: Thermal resistance, size, etc.

Tips: Determining needs, comparing options.

Conclusion

Importance of heat sinks and Aluinno's role.

Introduction

In the modern technological and industrial landscape, efficient heat dissipation is of paramount importance. From the high-performance processors in our computers to the power electronics in electric vehicles, heat sinks play a crucial role in maintaining the optimal operating temperature of various devices. Aluminium heat sinks, in particular, have emerged as a popular choice due to the excellent thermal conductivity and lightweight properties of aluminium. Aluinno, a leading company in the aluminium profile industry, has been at the forefront of providing high-quality aluminium heat sinks and related solutions. In this article, we will explore the world of aluminium heat sinks, from their basic principles to the manufacturing processes and the diverse applications they serve.

What Are Aluminium Heat Sinks

Definition

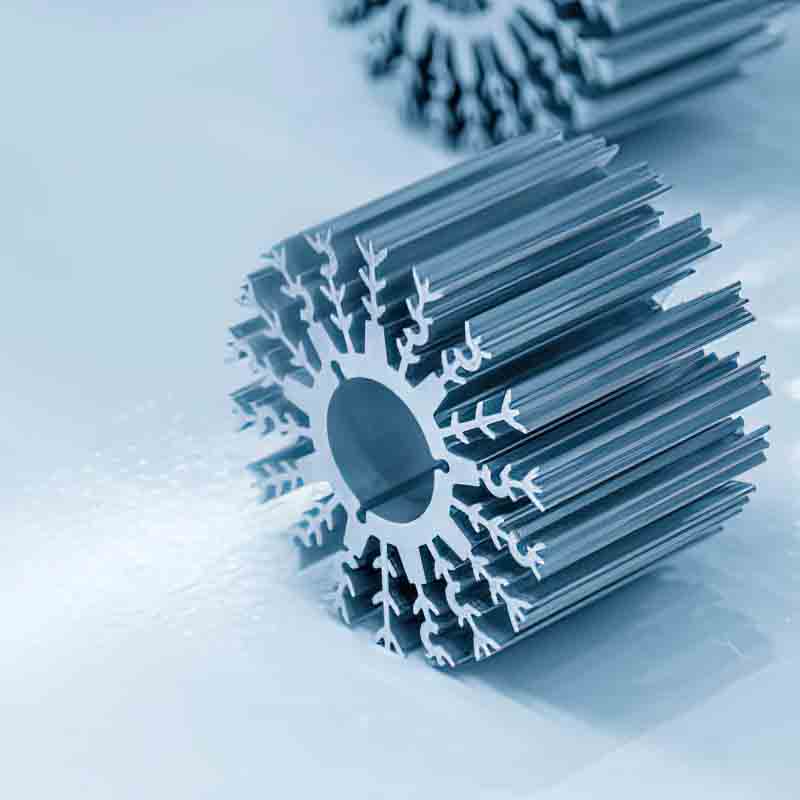

An aluminium heat sink is a passive heat exchanger that transfers heat generated by a device to the surrounding environment. It typically consists of a base plate and an array of fins. The base plate is in direct contact with the heat source, such as a microprocessor or a power transistor. The fins increase the surface area available for heat transfer, facilitating the dissipation of heat into the air. The choice of aluminium for heat sinks is primarily due to its relatively high thermal conductivity, which allows for efficient heat transfer within the material.

Working Principle

Heat transfer occurs through three main mechanisms: conduction, convection, and radiation. In an aluminium heat sink, conduction is the initial step where heat is transferred from the heat source to the base plate and then through the fins. Aluminium's good thermal conductivity enables rapid heat spread across the heat sink's structure. Convection comes into play as the heated air near the fins rises, drawing in cooler air from the surroundings. This continuous flow of air helps carry away the heat. Although radiation also contributes to heat dissipation, it is relatively less significant compared to conduction and convection in most common applications. For example, in a computer CPU cooling setup, the aluminium heat sink absorbs the heat from the CPU and transfers it to the air passing through the fins, preventing the CPU from overheating and ensuring stable performance.

The Role of Aluminum Profiles in Heat Sinks

Significance of Aluminum Profiles

Aluminum profiles form the backbone of heat sink design. They provide the necessary structural integrity to support the fins and ensure proper contact with the heat source. The extrusion process allows for the creation of complex shapes with precise dimensions, enabling the design of heat sinks optimized for specific thermal requirements. A well-designed aluminum profile can maximize the surface area available for heat transfer while minimizing the weight and size of the heat sink. This is crucial in applications where space is limited, such as in compact electronic devices.

Types of Aluminum Profiles Used

Industrial aluminum profiles are commonly used in heat sinks. Square and rectangular profiles are often employed for the base plate and the main body of the heat sink due to their stability and ease of manufacturing. Round profiles may be used in some designs for specific structural or aesthetic reasons. Additionally, custom aluminum profiles are gaining popularity. These can be tailored to fit unique device geometries or to enhance heat transfer in challenging thermal environments. For instance, in some high-power LED lighting fixtures, custom aluminum profiles with intricate fin designs are used to effectively dissipate the heat generated by the LEDs, ensuring long lifespan and reliable performance.

Extrusion Aluminium: The Manufacturing Process

Understanding Extrusion

The extrusion process of aluminium involves heating an aluminium billet to a malleable state and then forcing it through a die. The die determines the cross-sectional shape of the extruded profile. In the context of heat sinks, this process allows for the creation of the base plate and fin structures in a continuous and efficient manner. The extrusion pressure ensures a dense and uniform structure, which is essential for good thermal conductivity. Advanced extrusion techniques can also incorporate features like internal channels or grooves within the profile to further enhance heat transfer efficiency.

Advantages of Extrusion in Heat Sink Production

Extrusion offers several advantages in heat sink manufacturing. Firstly, it is a highly cost-effective method for producing large quantities of heat sinks with consistent quality. The ability to create complex shapes in a single step reduces the need for additional machining processes, saving both time and cost. Secondly, extrusion allows for a high degree of customization. By changing the die, manufacturers like Aluinno can produce a wide variety of heat sink profiles to meet different customer requirements. This flexibility is crucial in the fast-evolving electronics and industrial sectors where new devices with unique thermal needs are constantly emerging.

Custom Aluminum Solutions for Heat Sinks

Tailoring to Specific Needs

Custom aluminum heat sinks are designed to address the specific thermal challenges of individual applications. In the aerospace industry, for example, where space and weight are at a premium, custom heat sinks are engineered to fit precisely within the limited space available in aircraft avionics while providing the required heat dissipation. In medical equipment, such as MRI machines, custom heat sinks are designed to meet the strict safety and performance standards. Aluinno works closely with customers in these industries to understand their unique requirements and develop custom heat sink solutions that optimize thermal performance.

Design Considerations for Customization

When designing custom heat sinks, several factors need to be considered. The thermal load of the device determines the size and fin density of the heat sink. A higher thermal load requires a larger surface area and more efficient fin design. The operating environment also plays a crucial role. If the heat sink will be used in a dusty or corrosive environment, special coatings or materials may need to be incorporated. Additionally, the mechanical constraints of the device, such as available space and mounting options, must be taken into account. Aluinno's team of engineers uses advanced simulation software and thermal analysis tools to optimize the design of custom heat sinks, ensuring that they meet the specific needs of each application.

Industrial Aluminium Profiles in Heat Sinks

Applications in Various Industries

In the power electronics industry, aluminium heat sinks are widely used in inverters and converters. These devices generate significant amounts of heat during operation, and aluminium heat sinks help maintain their temperature within the safe operating range. In the automotive sector, electric vehicle battery management systems rely on aluminium heat sinks to cool the batteries, ensuring their efficiency and longevity. In the telecommunications industry, base stations and networking equipment use aluminium heat sinks to dissipate the heat generated by the electronic components, preventing signal interference and equipment failure.

Benefits in Industrial Settings

Industrial settings demand heat sinks that can withstand harsh conditions while providing reliable performance. Aluminium heat sinks offer excellent corrosion resistance, especially when properly coated or treated. They also have a high strength-to-weight ratio, making them suitable for applications where weight is a concern. Their durability ensures long service life, reducing the need for frequent replacements. This not only saves costs but also minimizes downtime in industrial processes. Aluinno's industrial aluminium heat sinks are manufactured to meet the strict quality standards of these industries, providing customers with reliable and efficient heat dissipation solutions.

aluinno's Expertise in Aluminium Heat Sinks

Product Range

Aluinno offers a comprehensive range of aluminium heat sinks, from standard off-the-shelf models to highly customized solutions. Our standard heat sinks are designed to meet the common thermal requirements of most electronic and industrial applications. They come in various sizes and fin configurations, providing customers with a quick and cost-effective solution. For more specialized applications, our custom heat sinks are engineered to the exact specifications of the customer. We can produce heat sinks with unique shapes, sizes, and thermal properties, ensuring optimal performance in even the most demanding applications.

Quality Assurance

Quality is at the core of Aluinno's manufacturing process. We use only high-quality aluminium alloys sourced from trusted suppliers. Our state-of-the-art extrusion facilities and advanced manufacturing processes ensure that each heat sink meets the highest standards of thermal conductivity and structural integrity. Stringent quality control checks are carried out at every stage of production, from the raw material inspection to the final product testing. This ensures that our customers receive heat sinks that are free from defects and perform reliably in their applications.

Customization and Consultation Services

At Aluinno, we understand that each customer's thermal management needs are unique. Our team of experienced engineers and technicians provides comprehensive customization and consultation services. We work closely with customers from the initial design phase to the final product delivery. We offer thermal analysis and design optimization to ensure that the chosen heat sink solution is the most suitable for the specific application. Our goal is to help customers achieve the best thermal performance while minimizing costs and maximizing the efficiency of their systems.

Choosing the Right Aluminium Heat Sink

Factors to Consider

When choosing an aluminium heat sink, several factors need to be carefully evaluated. The thermal resistance of the heat sink is a critical parameter. A lower thermal resistance indicates better heat transfer efficiency. The size and shape of the heat sink should match the available space and the heat source's dimensions. The fin design, including the fin height, thickness, and spacing, also affects the heat transfer performance. Additionally, the material quality and the manufacturing process used should be considered to ensure durability and reliability.

Tips for Making the Right Choice

To make the right choice, it is advisable to start by accurately determining the thermal requirements of the device. This can be done through thermal modeling or consulting with experts. Once the requirements are known, it is important to compare different heat sink options from reliable manufacturers like Aluinno. Look for products with good reviews and a proven track record. Consider the cost-benefit ratio, balancing the initial investment with the long-term performance and reliability of the heat sink. Finally, seek professional advice if needed to ensure that the chosen heat sink will meet the specific needs of the application.

Conclusion

Aluminium heat sinks are essential components in modern technology and industry, enabling the efficient dissipation of heat and ensuring the reliable operation of various devices. Aluinno's expertise in aluminium profiles and heat sink manufacturing, combined with its commitment to quality and customization, makes it a trusted partner for customers seeking optimal thermal management solutions. Whether it is a standard heat sink for a common electronic device or a highly customized solution for a specialized industrial application, Aluinno has the capabilities and experience to deliver. By understanding the principles and factors involved in choosing the right aluminium heat sink, customers can make informed decisions and ensure the thermal stability and performance of their systems. Contact Aluinno today to explore the wide range of aluminium heat sink options available and find the perfect solution for your specific needs.

En

En

Location:

Location: