Russia's Rusal's $250 Million Aluminum Sales Contract: A Game Changer for the Industry

OUTLINE

I. Introduction

II. Russia's Rusal and the Contract

III. Significance of Aluminum in Various Industries

IV. Aluminum Profile Manufacturing Process

V. aluinno as a Partner

VI. Market Impact and Future Prospects

VII. Conclusion

1. Introduction

Aluminum materials have firmly established themselves as an indispensable cornerstone in the modern industrial edifice. Their unique combination of properties, including lightweight, high strength, corrosion resistance, and excellent electrical and thermal conductivity, renders them highly adaptable across a vast spectrum of industries. From the towering skyscrapers that define city skylines to the high - speed trains that whisk passengers across long distances, from the fuel - efficient automobiles that dominate the roads to the advanced aerospace vehicles that traverse the skies, aluminum materials play a crucial role.

In the construction industry, aluminum profiles are extensively used in the fabrication of windows, doors, curtain walls, and structural frameworks. For instance, aluminum casement windows are highly favored for their sleek appearance, energy - efficient performance, and durability. Their lightweight nature not only simplifies the installation process but also reduces the overall load on the building structure. Moreover, the corrosion - resistant property of aluminum ensures that these windows maintain their aesthetic appeal and functionality even in harsh environmental conditions.

The transportation sector also heavily relies on aluminum materials. In the automotive industry, the use of aluminum in vehicle manufacturing has been on the rise. Extrusion aluminium is used to create various components such as engine blocks, body frames, and interior trims. By replacing heavier materials with aluminum, automakers can significantly reduce the weight of vehicles, thereby improving fuel efficiency and reducing emissions. This trend is in line with the global push towards more sustainable transportation solutions. In the aerospace industry, the demand for lightweight yet strong materials is even more critical. Aluminum is used to construct aircraft fuselages, wings, and other vital components. The high strength - to - weight ratio of aluminum makes it an ideal choice for aerospace applications, as it helps to reduce the overall weight of the aircraft, which in turn improves fuel efficiency, increases payload capacity, and extends the range of the aircraft.

The industrial sector also benefits greatly from the use of aluminum materials. Industrial aluminium profile finds applications in the construction of machinery frames, conveyor systems, and workbenches. Their versatility allows for easy customization to meet the specific requirements of different industrial processes. For example, in a manufacturing plant, custom aluminum frames can be designed and fabricated to support heavy machinery or to create efficient conveyor systems that optimize the flow of materials.

As we look ahead to 2025, the price of aluminum is expected to be a key factor that will significantly impact the supply and demand dynamics of aluminum materials. Fluctuations in aluminum prices can have far - reaching consequences for various industries that rely on these materials. A rise in aluminum prices may lead to a decrease in demand as companies seek to cut costs by either reducing their consumption of aluminum or substituting it with other materials. On the other hand, higher prices may also incentivize producers to increase their supply, provided that they can do so profitably. Conversely, a decline in aluminum prices may stimulate demand as aluminum becomes a more cost - effective option for businesses. However, it could also lead to a reduction in supply if producers find it unprofitable to continue operating at lower price levels.

Against this backdrop, it becomes imperative for industry players, policymakers, and investors to closely monitor the trends in 2025 aluminum prices and understand their implications for the supply and demand of aluminum materials. This understanding will enable them to make informed decisions, manage risks effectively, and capitalize on emerging opportunities. In the following sections of this blog, we will delve deeper into the factors that are likely to influence the 2025 aluminum prices, analyze how these price changes will impact the supply and demand of aluminum materials in different industries, and explore some of the strategies that businesses can adopt to navigate the challenges and opportunities presented by these market dynamics. aluinno, as a company deeply involved in the aluminum industry, is also closely watching these trends and is committed to providing high - quality aluminum products and solutions to meet the evolving needs of our customers.

2. Russia's Rusal and the Contract

2.1 Russia's Rusal: A Powerhouse in the Aluminum Industry

Rusal is a behemoth in the global aluminum arena. It boasts state-of-the-art production facilities and a vast network of mines and refineries, ensuring a stable supply of high-quality raw materials. Its technological prowess allows it to produce aluminum with consistent quality and meet the stringent demands of customers worldwide. Over the years, Rusal has built a solid reputation for its reliability and innovation, constantly pushing the boundaries of what is possible in aluminum production.

2.2 The $250 Million Sales Contract: Key Details

The $250 million contract is a significant milestone for Rusal. While specific details regarding the buyers and the exact product specifications are yet to be fully disclosed, it is clear that this deal will involve a substantial volume of aluminum products. The contract is likely to span over a certain period, during which Rusal will be responsible for ensuring timely delivery of the agreed-upon aluminum quantities. This not only provides a major boost to Rusal's revenue stream but also has the potential to reshape the market dynamics in the aluminum industry.

3. The Significance of Aluminum in Various Industries

3.1 Construction Industry

3.1.1 Aluminum Profiles in Building Structures

In the construction sector, aluminum profiles play a vital role. They are widely used in building frames, providing structural integrity while reducing the overall weight of the building. This is of utmost importance in modern architecture, where there is an increasing emphasis on energy efficiency and sustainable design. Aluminum's resistance to corrosion ensures the longevity of the building structure, even in harsh environmental conditions. For example, in high-rise buildings, aluminum profiles are used in curtain walls, which not only enhance the aesthetic appeal of the building but also offer excellent thermal insulation and soundproofing properties.

3.1.2 Aluminium Casement Windows: A Popular Choice

Aluminium casement windows have become a preferred option for many builders and homeowners. Their sleek design and smooth operation add a touch of elegance to any building. The inherent strength of aluminum allows for the creation of large, clear glass panes, maximizing natural light ingress. Moreover, the corrosion resistance of aluminum ensures that the windows maintain their functionality and appearance over time. In areas with high humidity or coastal regions, aluminium casement windows are particularly advantageous as they can withstand the corrosive effects of saltwater and moisture.

3.2 Industrial Applications

3.2.1 Industrial Aluminium Profiles: Versatile Solutions

Industrial machinery and manufacturing rely heavily on aluminum profiles. They are used in the construction of machine frames, conveyor systems, and robotic arms. The lightweight nature of aluminum reduces the energy consumption of machinery during operation, while its high strength-to-weight ratio enables the design of more efficient and durable equipment. In the automotive manufacturing industry, for instance, aluminum profiles are used in the production of car bodies and chassis, contributing to improved fuel efficiency and vehicle performance.

3.2.2 Custom Aluminum Solutions for Industrial Needs

In many industrial applications, standard aluminum profiles may not meet the specific requirements. This is where custom aluminum solutions come into play. For example, in the aerospace industry, components need to withstand extreme temperatures, high pressures, and heavy loads. Custom aluminum profiles are designed with precision to meet these exacting demands. Aluinno specializes in providing such custom solutions, working closely with clients to understand their unique needs and develop aluminum profiles that deliver optimal performance.

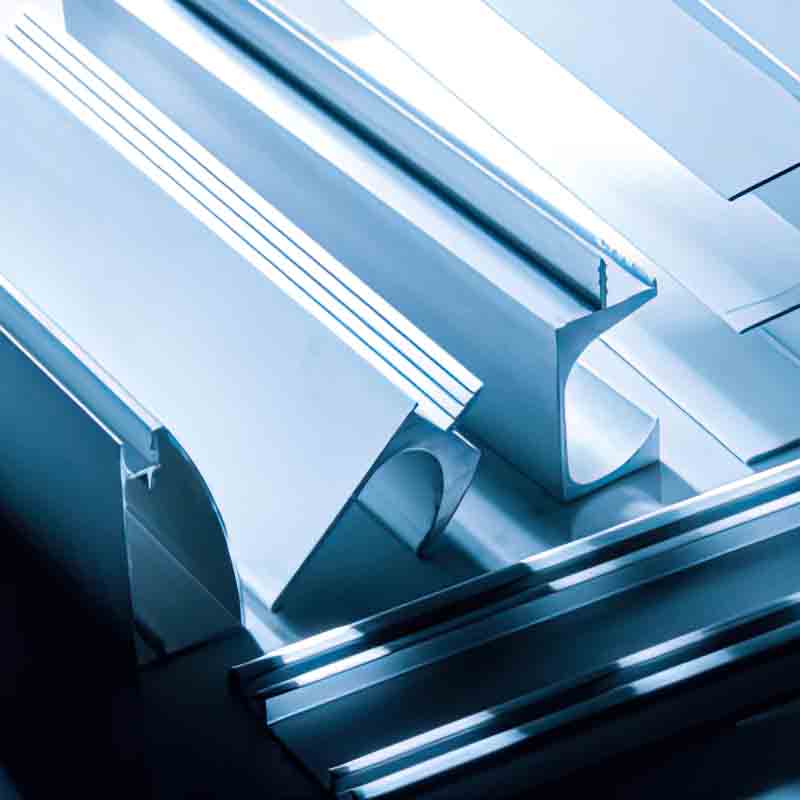

4. Aluminum Profile Manufacturing Process

4.1 Extrusion Aluminium: The Core Process

The extrusion process is the heart of aluminum profile manufacturing. It involves heating aluminum billets to a specific temperature and then forcing them through a precisely designed die. This process imparts the desired shape to the aluminum, creating profiles with high dimensional accuracy and smooth surfaces. The choice of die determines the cross-sectional shape of the profile, ranging from simple squares and rectangles to complex custom designs. During extrusion, strict control of temperature, pressure, and speed is essential to ensure the quality of the final product.

4.2 Quality Control and Assurance

At Aluinno, quality control is an integral part of the manufacturing process. We start with rigorous inspection of raw materials to ensure their purity and conformity to standards. During production, advanced monitoring systems are employed to track key parameters such as temperature and pressure. After extrusion, each aluminum profile undergoes a comprehensive inspection for dimensional accuracy, surface finish, and mechanical properties. Only profiles that meet our strict quality standards are allowed to leave the factory, ensuring that our customers receive products of the highest quality.

5. aluinno: Your Trusted Aluminum Partner

5.1 aluinno's Product Range

Aluinno offers a diverse range of aluminum profiles to cater to the varied needs of different industries. Our product portfolio includes standard profiles such as square, round, and rectangular ones, which are readily available and cost-effective for general applications. Additionally, we have an extensive selection of custom profiles designed to meet the specific requirements of clients in sectors like aerospace, automotive, and construction. Whether it's a unique shape for an architectural detail or a high-strength profile for industrial machinery, we have the expertise and capabilities to deliver.

5.2 Customization Services

Our customization services set us apart from the competition. We have a team of highly skilled engineers and designers who work closely with clients from the initial concept stage to the final production. We use advanced CAD/CAM technology to create prototypes and optimize designs, ensuring that the custom aluminum profiles meet the exact specifications and performance requirements of the project. This personalized approach has earned us the trust of many clients who rely on us for their complex and demanding aluminum profile needs.

5.3 Quality and Reliability

Quality and reliability are the hallmarks of Aluinno's products. We source our raw materials from trusted suppliers and adhere to strict quality management systems throughout the production process. Our state-of-the-art manufacturing facilities are equipped with the latest technology, enabling us to produce aluminum profiles with consistent quality. We also provide comprehensive after-sales support, ensuring that our customers have a seamless experience when using our products.

6. Market Impact and Future Prospects

6.1 Impact of Russia's Rusal's Contract on the Aluminum Market

The Rusal contract is expected to have a significant impact on the aluminum market. The increased supply of aluminum resulting from this contract may lead to a downward pressure on prices in the short term. However, it also presents opportunities for downstream industries to access aluminum at more favorable rates, potentially stimulating growth in sectors such as construction and manufacturing. On the other hand, competitors may need to adjust their strategies to maintain their market share in the face of this new supply influx.

6.2 Future Trends in the Aluminum Industry

Looking ahead, the aluminum industry is poised for further growth and innovation. With the increasing focus on sustainability, there will be a greater demand for aluminum in applications such as renewable energy systems and electric vehicles. Additionally, advancements in manufacturing technologies will enable the production of even more complex and high-performance aluminum profiles. Aluinno is committed to staying at the forefront of these trends, investing in research and development to continuously improve our products and services.

7. Conclusion

In conclusion, Russia's Rusal's $250 million aluminum sales contract is a significant event that will have a profound impact on the aluminum industry. The importance of aluminum in various industries, from construction to industrial applications, cannot be overstated. At Aluinno, we are well-equipped to navigate the changing market dynamics and continue to provide our customers with high-quality aluminum profiles and customized solutions. Whether you are involved in a large-scale construction project or require specialized aluminum components for industrial machinery, Aluinno is your trusted partner. We look forward to contributing to the success of your projects and playing an active role in the future development of the aluminum industry.

En

En

Location:

Location: