The Ultimate Guide to Know Everything of Aluminum Profiles

The Ultimate Guide to Aluminum Profiles: Everything You Need to Know

Aluminum profiles are a key component in modern construction and manufacturing. Their versatility, strength, and lightweight nature have made them indispensable across various industries. But what exactly are aluminum profiles? How are they made, and why are they so popular? In this comprehensive guide, we will explore every aspect of aluminum profiles, from their types and manufacturing process to their wide-ranging applications and environmental benefits.

In This Post:

1. What Are Aluminum Profiles?

2. Types of Aluminum Profiles

- Standard, Custom, Extruded, and Modular Profiles

3. The Aluminum Profile Manufacturing Process

- Raw Material Extraction, Extrusion, Cooling, and Finishing

4. Advantages of Aluminum Profiles

- Lightweight, Corrosion Resistance, Design Versatility, Strength-to-Weight Ratio

5. Applications of Aluminum Profiles

- Construction, Transportation, Electronics, and Furniture

6. Customizing Aluminum Profiles

- Shape, Size, and Surface Treatments (Anodizing, Coating, Painting)

7. Comparing Aluminum Profiles with Other Materials

- Aluminum vs. Steel, Plastic, and Wood

8. Sustainability of Aluminum Profiles

- Recyclability, Environmental Impact, and Green Building Uses

9. Conclusion

What Are Aluminum Profiles?

Aluminum profiles are formed by extruding aluminum into various shapes and sizes, allowing for endless possibilities in terms of design and functionality. These profiles are widely used in industries ranging from construction and transportation to electronics and home furnishings. The primary advantage of aluminum is its high strength-to-weight ratio, which makes it a preferred choice for applications where both durability and lightness are required.

Why Are Aluminum Profiles So Popular?

Aluminum profiles are renowned for their versatility, sustainability, and performance. They offer several advantages over other materials, including:

· Lightweight nature: Aluminum is about one-third the weight of steel, making it ideal for projects where weight reduction is important.

· Corrosion resistance: Unlike iron or steel, aluminum doesn’t rust, making it suitable for outdoor and marine applications.

· Recyclability: Aluminum can be recycled without losing its properties, making it one of the most sustainable materials available.

· Customizability: Aluminum profiles can be tailored into various shapes and sizes to suit specific applications, offering unmatched flexibility.

Aluminum profiles have continued to gain traction globally because of their adaptability and the modern manufacturing processes that allow manufacturers to fine-tune profiles to meet specific design needs. Whether you're building skyscrapers or assembling aircraft components, aluminum profiles have become a go-to solution.

Types of Aluminum Profiles

There are several types of aluminum profiles available, each designed for specific applications. The choice of profile largely depends on the function it needs to serve and the conditions it will be exposed to.

Standard Aluminum Profiles

Standard aluminum profiles are mass-produced and come in common shapes like angles, channels, and tubes. These profiles are often used for general construction purposes where customized designs are not necessary. They are readily available and cost-effective, making them suitable for everyday construction tasks such as window frames, stair railings, and other basic structural elements.

Common Shapes of Standard Profiles

· Angles: Often used in framing systems, angles provide structural support.

· Channels: Ideal for securing other components and commonly used in framing applications.

· Tubes: Hollow profiles are lightweight yet strong, often used in automotive and aerospace designs.

Custom Aluminum Profiles

Custom profiles are specifically designed to meet the unique requirements of a particular project. They can be created in almost any shape or size, making them perfect for applications where standard profiles won’t suffice. Custom profiles are often utilized in specialized projects such as architectural features, furniture design, and machine parts.

Advantages of Custom Aluminum Profiles

· Tailored Design: Custom profiles allow for intricate and complex shapes, which cannot be achieved with standard profiles.

· Improved Functionality: Designs can be optimized for specific mechanical properties such as load-bearing strength or heat dissipation.

· Aesthetic Flexibility: Custom profiles can be anodized or finished to match specific aesthetic requirements, which is crucial for visible applications in modern architecture.

Extruded Aluminum Profiles

Extruded profiles are the most common form of aluminum profiles. During the extrusion process, a heated aluminum billet is pushed through a die, forming the profile’s shape. Extruded profiles are used in a wide variety of applications, including framing systems, automotive components, and architectural structures. The extrusion process ensures high consistency and precision in the final product.

The Importance of the Extrusion Process

Extrusion allows manufacturers to create long, continuous shapes that maintain uniform cross-sections. This is especially important in industries that require large quantities of profiles with precise dimensions, such as the automotive and construction sectors. The extrusion process also makes it easy to add functional features to profiles, like slots for fastening components together, making them an excellent choice for modular construction.

Modular Aluminum Profiles

Modular profiles are designed to be part of a larger system. These profiles are used in applications such as conveyors, automation systems, and workstations, where they can be easily assembled and disassembled. The modularity of these profiles makes them a favorite in industries that require flexible, changeable structures. Engineers often use modular aluminum profiles to build assembly lines, automation equipment, and lab workstations.

Common Uses of Modular Aluminum Profiles

· Workstations: Industrial environments often use modular profiles for customizable workbenches.

· Automation: Modular profiles are employed in conveyor systems or other manufacturing setups that need to be reconfigured frequently.

· Retail Displays: Easy to assemble and dismantle, modular profiles are popular for creating dynamic retail display systems.

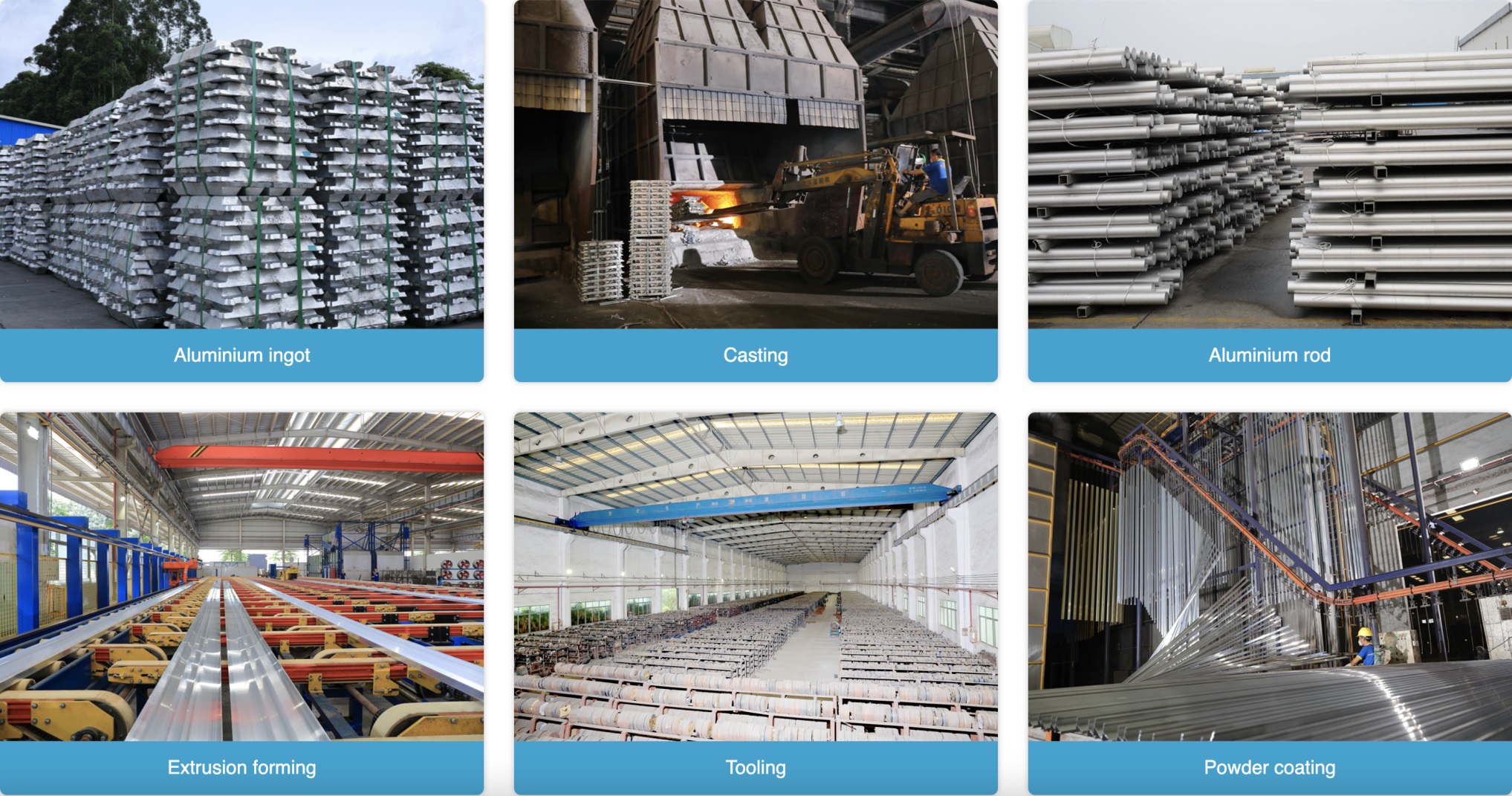

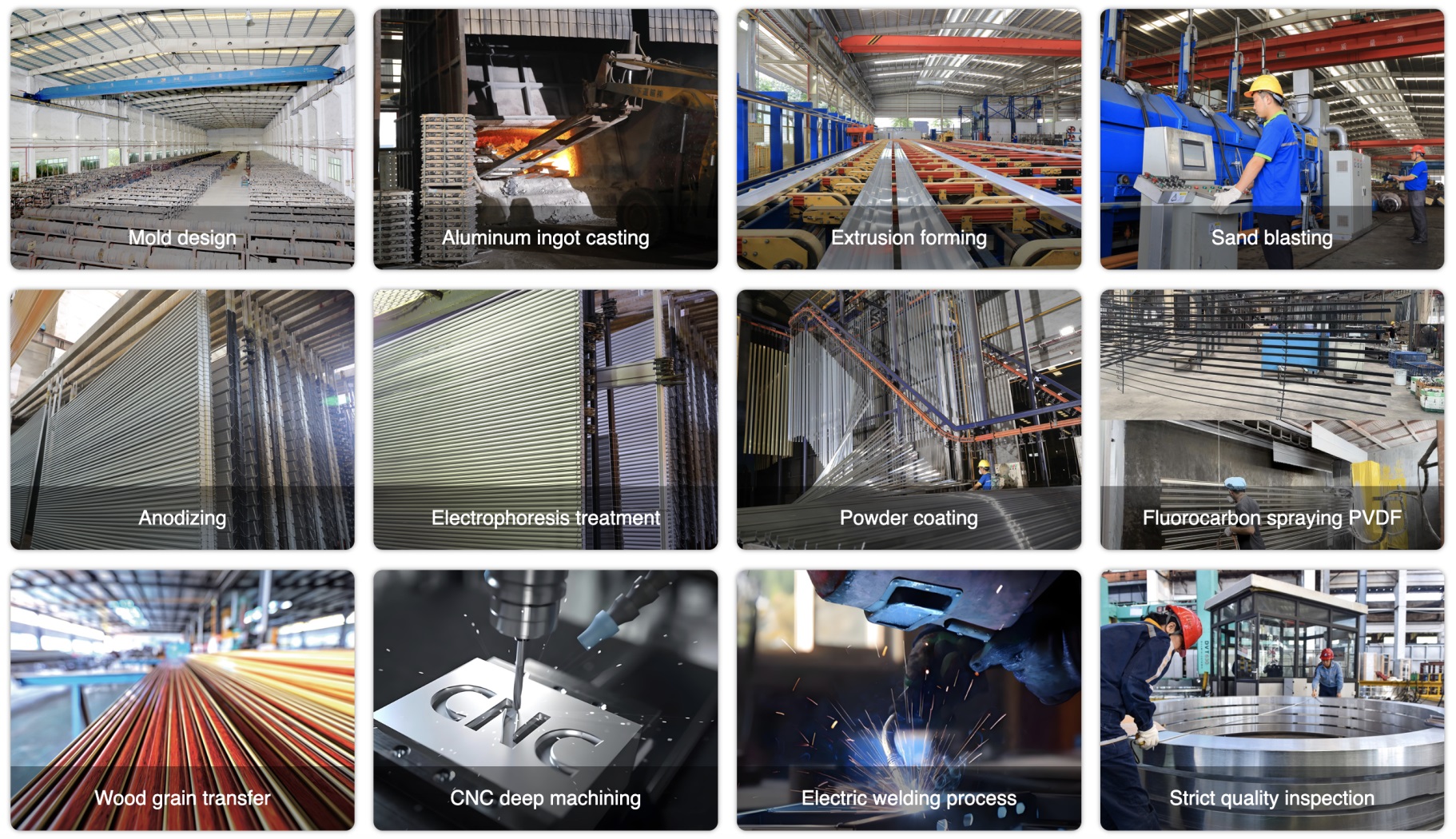

The Aluminum Profile Manufacturing Process

Understanding how aluminum profiles are made can give us better insight into why they’re so versatile and popular. The manufacturing process involves several stages, each contributing to the final product's strength, durability, and precision.

Raw Aluminum Extraction and Preparation

The process begins with the extraction of bauxite, a raw material that is refined into alumina. Alumina is then smelted in a process called electrolytic reduction, which results in pure aluminum metal. This raw aluminum is then formed into billets or logs, which will later be heated and extruded into profiles.

Environmental Concerns of Aluminum Extraction

It’s important to acknowledge that while aluminum extraction is energy-intensive, the industry has made significant strides in reducing environmental impacts through the use of renewable energy sources like hydropower. This makes aluminum an environmentally responsible choice when coupled with recycling initiatives.

The Extrusion Process

Extrusion is the most common method used to create aluminum profiles. Here’s a breakdown of the steps involved:

Heating the Aluminum Billets

Before extrusion, aluminum billets are heated to make them more malleable. The heating temperature is typically around 400-500 degrees Celsius, allowing the aluminum to be shaped without losing its strength.

Pushing Through the Die

Once heated, the aluminum billet is forced through a die, which has been shaped into the desired profile. The die is a crucial component, as it determines the final shape and dimensions of the profile.

Cooling and Stretching

After extrusion, the profile is cooled rapidly to retain its shape. In some cases, the profile is also stretched to align the metal’s internal structure, improving its overall strength and resistance to stress. Stretching the profiles helps eliminate any internal stresses introduced during the extrusion process, making them more robust for heavy-duty applications.

Cutting and Finishing

The final step is cutting the extruded aluminum profile to the required length. After cutting, the profile may undergo further finishing processes like anodizing or powder coating to improve its appearance and corrosion resistance. The finishing process enhances the aesthetic and mechanical properties, ensuring the profile can withstand harsh environmental conditions.

Advantages of Aluminum Profiles

Aluminum profiles have numerous advantages that make them a top choice for engineers, architects, and manufacturers. From their weight to corrosion resistance, these profiles consistently outperform alternative materials in several key areas.

Lightweight and Durable

Aluminum’s lightweight nature is one of its most significant advantages. It offers high strength while being considerably lighter than materials like steel, making it easier to handle and transport. This property makes aluminum profiles ideal for applications in aerospace, automotive, and construction.

Use in Aerospace and Automotive Sectors

In aerospace, reducing the weight of aircraft components can dramatically improve fuel efficiency. Similarly, automotive manufacturers often use aluminum profiles to reduce vehicle weight, which helps improve fuel economy while maintaining structural integrity. Whether in car frames, aircraft wings, or even bicycle components, aluminum profiles deliver durability without adding unnecessary weight.

Corrosion Resistance

Aluminum naturally forms a protective oxide layer when exposed to air, which protects it from rust and corrosion. This makes aluminum profiles ideal for outdoor applications, such as window frames, roofing, and marine equipment, where they are exposed to moisture and harsh weather conditions.

Aluminum’s Role in Marine Applications

Due to its superior corrosion resistance, aluminum is widely used in the marine industry. Ships, boat hulls, and even offshore platforms utilize aluminum profiles, as the material can withstand saltwater without the need for frequent maintenance or replacement, making it a cost-effective solution.

Versatility in Design

Aluminum profiles can be extruded into an almost limitless range of shapes, allowing designers to create complex and highly customized structures. Whether you need intricate designs for architectural projects or robust frameworks for industrial machinery, aluminum profiles can be tailored to meet those needs.

Architectural Applications

Architects love aluminum profiles because they can be shaped into almost any design. From sleek modern facades to complex curtain wall systems, aluminum profiles provide the flexibility needed to bring visionary designs to life. The material can also be easily colored or textured using anodizing or powder coating, giving architects more creative freedom.

High Strength-to-Weight Ratio

One of the most important features of aluminum is its excellent strength-to-weight ratio. It can support significant loads without adding much weight, which is particularly important in industries like transportation and construction, where weight reduction can lead to increased efficiency and reduced energy consumption.

High Load Applications

Despite its lightweight characteristics, aluminum is remarkably strong. This makes it suitable for load-bearing applications in structures like bridges, balconies, and building frameworks. Many skyscrapers incorporate aluminum profiles in their structural frameworks to take advantage of both strength and weight savings.

Applications of Aluminum Profiles

Aluminum profiles are used across a wide range of industries due to their versatility and strength. Below are some of the most common applications.

Construction Industry

Aluminum profiles play a pivotal role in modern construction. They are used in building facades, curtain walls, and window frames, thanks to their durability and resistance to the elements. Additionally, aluminum profiles are a favorite for structural components due to their strength and ability to be customized to meet architectural requirements.

Use in Curtain Wall Systems

Curtain wall systems are non-load-bearing exterior walls that separate the interior of a building from the outdoors. Aluminum profiles are often used in these systems due to their strength, lightness, and ability to be anodized or powder-coated for aesthetic purposes.

Transportation Industry

In the automotive and aerospace industries, reducing weight is crucial to improving fuel efficiency and performance. Aluminum profiles offer the perfect solution, as they provide strength and durability while significantly reducing overall weight. You’ll find aluminum profiles used in car chassis, airplane wings, and even bicycle frames.

Rail and Mass Transit

Aluminum profiles are also used extensively in the rail and mass transit industries. The material’s lightweight properties help reduce the overall weight of trains and subway cars, leading to energy savings and improved speed. Additionally, aluminum’s corrosion resistance ensures that rail vehicles can operate in harsh conditions without degradation.

Electrical and Electronics Industry

Aluminum’s excellent thermal conductivity makes it a natural choice for electrical components and heat sinks. Aluminum profiles are often used in cooling systems for computers, LED lights, and other electronic devices. Additionally, the lightweight nature of aluminum makes it ideal for creating cable trays, housings, and electrical enclosures.

Heat Sinks and Cooling Systems

In electronics, effective heat dissipation is critical to ensuring longevity and performance. Aluminum’s high thermal conductivity, combined with its ease of extrusion into intricate shapes, makes it the ideal material for heat sinks. It is widely used in LED lighting systems, computer components, and other devices where heat management is crucial.

Furniture and Interior Design

Aluminum profiles are also widely used in furniture and interior design. Their sleek, modern appearance makes them a popular choice for office furniture, partitions, shelving systems, and more. The durability of aluminum ensures that these furniture pieces are long-lasting, while their lightweight nature allows for easy rearrangement.

Modular Furniture Systems

In recent years, aluminum profiles have gained popularity in modular furniture systems. Their ability to be easily assembled, disassembled, and reconfigured makes them ideal for creating flexible workspaces. This is particularly important in industries where office layouts change frequently, such as in tech startups and co-working spaces.

Customizing Aluminum Profiles

One of the standout features of aluminum profiles is their ability to be customized to meet specific needs. From the shape and size to the finish and additional features, aluminum profiles can be tailored to fit almost any project.

Shape and Size Customization

With the extrusion process, aluminum can be formed into any shape, no matter how complex. Whether you need standard shapes like channels and angles or intricate custom designs, aluminum profiles can be manufactured to exact specifications. Sizes can also be adjusted based on load-bearing requirements and other design factors.

Tailored Structural Elements

Custom aluminum profiles are especially valuable in projects that require precise structural components. Architects, engineers, and designers often use custom profiles to build frameworks, window systems, or even entire building facades that meet specific design and functional criteria.

Surface Treatment Options

Aluminum profiles can be finished in a variety of ways to improve their performance and appearance. The most common finishing techniques include:

Anodizing

Anodizing is an electrochemical process that thickens the natural oxide layer on aluminum, enhancing its corrosion resistance and allowing for color options. Anodized aluminum profiles are commonly used in architectural applications due to their aesthetic appeal and durability.

Powder Coating

Powder coating provides a smooth, durable finish that protects aluminum profiles from corrosion, scratches, and wear. Powder-coated aluminum is available in a wide range of colors and is often used in furniture, automotive parts, and outdoor structures.

Painting

For projects that require specific colors or textures, aluminum profiles can also be painted. While painting may not offer the same level of durability as anodizing or powder coating, it is a versatile and cost-effective finishing option.

Comparing Aluminum Profiles with Other Materials

When choosing a material for construction, manufacturing, or design, it’s essential to consider how aluminum profiles compare to other options like steel, plastic, or wood.

Aluminum vs. Steel

Steel is stronger than aluminum, but it’s also much heavier. In applications where weight is a concern, aluminum profiles offer a better balance of strength and lightness. Steel is more prone to rust, requiring treatments or coatings, whereas aluminum’s natural corrosion resistance makes it ideal for outdoor and marine applications.

Cost Considerations

While steel may be less expensive initially, its need for protective coatings and regular maintenance makes it a costlier material over time. Aluminum profiles, though more expensive upfront, require little maintenance and provide long-term savings, particularly in projects exposed to the elements.

Aluminum vs. Plastic

While plastic is lightweight and inexpensive, it cannot match aluminum in terms of durability, strength, or heat resistance. For applications requiring long-term performance and strength, aluminum profiles are a far superior choice.

Sustainability and Environmental Impact

Plastic is a less sustainable option than aluminum because it’s often derived from fossil fuels and has limited recyclability. Aluminum, on the other hand, can be recycled indefinitely without losing its properties, making it the more eco-friendly option in the long run.

Aluminum vs. Wood

Wood is often used for aesthetic purposes, but it doesn’t have the same strength or longevity as aluminum. Aluminum profiles offer fire resistance, longer lifespan, and the ability to be shaped into complex designs, making them a more versatile option for structural applications.

Maintenance and Durability

Wood requires regular maintenance, such as staining or sealing, to protect it from moisture and insects. Aluminum, on the other hand, is virtually maintenance-free and can last for decades without significant wear, making it a more durable option.

Sustainability of Aluminum Profiles

As environmental concerns grow, the sustainability of building materials becomes more critical. Aluminum profiles offer several eco-friendly advantages, making them a preferred material for green construction projects.

Recyclability of Aluminum

Aluminum is one of the most recyclable materials on the planet. It can be recycled indefinitely without losing its properties, and recycling aluminum requires only 5% of the energy needed to produce new aluminum from raw materials. This makes aluminum profiles an excellent choice for projects that prioritize sustainability.

The Closed-Loop Recycling Process

The recycling process for aluminum is highly efficient, with minimal waste. In fact, nearly 75% of all aluminum ever produced is still in use today, making it one of the most sustainable materials available. The closed-loop nature of aluminum recycling means that profiles can be repurposed again and again without compromising their quality or performance.

Environmental Impact of Aluminum Production

Although the production of aluminum is energy-intensive, the industry has made significant strides in reducing its carbon footprint. Many aluminum manufacturers now use renewable energy sources, such as hydropower, to power their operations. Additionally, the widespread recycling of aluminum helps offset the environmental impact of its initial production.

Aluminum Profiles in Green Building

Aluminum profiles are increasingly used in green building projects, where sustainability and energy efficiency are priorities. Aluminum’s recyclability, durability, and thermal efficiency contribute to LEED certifications and other environmental building standards.

Energy Efficiency and Thermal Performance

In addition to being sustainable, aluminum profiles can contribute to a building’s energy efficiency. Their ability to support large windows and curtain wall systems allows for increased natural light, reducing the need for artificial lighting and lowering energy consumption. Aluminum’s reflective properties can also help reduce the heat load on a building, further enhancing energy efficiency.

Conclusion

Aluminum profiles are an essential material in today’s construction, transportation, and manufacturing industries. Their combination of lightness, strength, corrosion resistance, and recyclability makes them an unbeatable choice for a wide range of applications. Whether you’re looking to build a high-rise, manufacture automotive parts, or design furniture, aluminum profiles offer the perfect balance of performance and sustainability.

The versatility of aluminum profiles makes them an ideal material for an almost limitless range of industries, including aerospace, automotive, electronics, and construction. As the demand for sustainable, lightweight, and durable materials continues to grow, aluminum profiles are expected to play an even larger role in shaping the future of industrial design and engineering.

By understanding the unique properties, applications, and benefits of aluminum profiles, you can make informed decisions that will enhance the efficiency, durability, and sustainability of your projects.

Why Choose Aluinno Aluminum

Quality and Precision

At Aluinno Aluminum, quality is our top priority. We have implemented a comprehensive quality control system that monitors every stage of the production process. From the sourcing of raw materials to the final inspection of the finished profiles, we adhere to strict quality standards. Our experienced quality control team uses advanced testing equipment to ensure that each aluminum profile meets or exceeds industry standards. We use only high-quality aluminum alloys, sourced from reliable suppliers, to ensure the strength, durability, and finish of our products.

Customization Capabilities

Our ability to create custom profiles is one of our greatest strengths. We have a team of highly skilled engineers and designers who work closely with customers to understand their unique requirements. We can develop custom designs, shapes, and finishes to meet the specific needs of any project. Our state-of-the-art manufacturing facilities allow us to produce small and large quantities of custom profiles with high precision and efficiency.

Quick Response and Delivery

We understand the importance of time in today's fast-paced business environment. That's why we have a dedicated customer service team that provides quick response times to inquiries. Our efficient production and logistics systems enable us to deliver products in a timely manner. We work with reliable shipping partners to ensure that your aluminum profiles arrive at their destination safely and on time.

Global Support

Aluinno Aluminum provides after-sales technical support worldwide. Our team of experts is available to assist customers with any questions or issues they may have. Whether it's installation advice, product specifications, or troubleshooting, we are committed to providing excellent customer service. We have a global network of distributors and partners, making it easy for customers to access our products and services.

In conclusion, aluminum profiles from Aluinno Aluminum are versatile, durable, and high-quality products that have a wide range of applications across multiple industries. Our commitment to innovation, quality, and customer service sets us apart in the market. Whether you are in the construction, automotive, electronics, or furniture industry, our aluminum profiles can meet your needs. Contact us today to learn more about our products and services and see how Aluinno Aluminum can help you achieve your goals.

En

En

Location:

Location: