Building the Future: Aluminum Profiles in Global Urbanization

Introduction

In the contemporary era of rapid global urbanization, the significance of suitable building materials cannot be overstated. Presently, over 55% of the world's population resides in urban areas, and this proportion is projected to escalate to 68% by 2050. This upward trend in urban population has led to an insatiable demand for building materials that can not only withstand the test of time but also adhere to the principles of sustainable development. Aluinno Aluminum Profiles, renowned for their high - quality standards such as ISO 9001 - 2008 and ISO 14001 - 2008, have emerged as a prime choice in this regard. These profiles possess a unique combination of properties, namely lightweight, strength, and recyclability, which are highly desirable for urban construction projects.

The manufacturing process of Aluinno Aluminum Profiles is a meticulous one. It commences with a comprehensive mold design phase, where precision and innovation are key. During this stage, engineers at Aluinno utilize the latest software and technology to create molds that can produce aluminum profiles with the most intricate shapes and accurate dimensions. This is crucial as it sets the foundation for the subsequent production steps. Subsequently, incoming inspection ensures that only the finest raw materials are used. The company has strict quality control measures in place, and every batch of raw aluminum is thoroughly examined for its purity, alloy composition, and any potential defects.

The extrusion process then shapes the aluminum into the desired profiles. This process involves forcing the aluminum through a die under high pressure, which gives the aluminum its specific cross - sectional shape. Aluinno has invested in state - of - the - art extrusion equipment, which allows for a high degree of precision and consistency in the production of profiles. After extrusion, cutting is carried out to achieve the appropriate lengths. This step is not as simple as it may seem, as it requires accurate measurement and cutting techniques to ensure that the final profiles meet the exact specifications required for different applications.

Quality inspection at multiple stages guarantees that the profiles meet the stringent standards set by the company. These inspections involve both non - destructive and destructive testing methods. Non - destructive methods such as ultrasonic testing are used to detect any internal flaws without damaging the profiles, while destructive tests like tensile strength testing are carried out on sample profiles to ensure they meet the required mechanical properties. CNC & machining processes are employed to add further refinement. Computer - controlled machining allows for precise milling, drilling, and other operations on the profiles, enabling the creation of custom - made features or the fitting of additional components.

Surface treatment techniques such as anodizing, powder - coating, or electrophoresing are utilized to enhance the profiles' durability and aesthetic appeal. Anodizing, for example, creates a protective oxide layer on the surface of the aluminum, which not only improves its corrosion resistance but also allows for the addition of color. Powder - coating provides a smooth and durable finish, while electrophoresing can offer a more even coating distribution. Performance test is carried out to ensure that the profiles can perform optimally under various conditions. These tests may include exposure to extreme temperatures, humidity, and mechanical stress to simulate real - world scenarios. Finally, packing and loading are executed with care to ensure the profiles reach their destinations intact. Additionally, heat treatment options like T4, T5, or T6 can be applied to modify the mechanical properties of the profiles, making them even more suitable for different applications.

The Urbanization Trend

The pace of global urbanization is accelerating at an unprecedented rate, exerting tremendous pressure on urban infrastructure. Developing regions, especially in the Asia - Pacific area, are witnessing explosive growth. Countries like China and India are at the forefront of this growth spurt. In these regions, the demand for aluminum profiles in construction has been skyrocketing. This is primarily due to the need to accommodate the ever - increasing urban population. Cities are expanding both horizontally and vertically, and the unique properties of Aluinno Aluminum Profiles play a crucial role in this expansion.

The lightweight nature of these profiles is a game - changer. For instance, in high - density urban areas where land is scarce, it enables the construction of taller and more complex structures. Profiles with different shapes, such as Hollow Beam Profile, Triangular, and Square, offer architects and engineers greater flexibility in design. Their high strength - to - weight ratio allows for better load - bearing capabilities, which is essential for the safety and stability of large - scale urban constructions. Moreover, the lightweight property also reduces the overall weight of the building, which in turn can lead to savings in foundation construction costs.

Another aspect of urbanization that benefits from aluminum profiles is the need for rapid construction. In many urban development projects, time is of the essence. The ease of handling and installation of these profiles can significantly speed up the construction process. For example, in modular construction methods, where pre - fabricated components are assembled on - site, Aluinno Aluminum Profiles can be easily integrated into the modular units, reducing the on - site construction time and minimizing disruption to the surrounding environment.

The applications of aluminum profiles in construction are extensive and diverse.

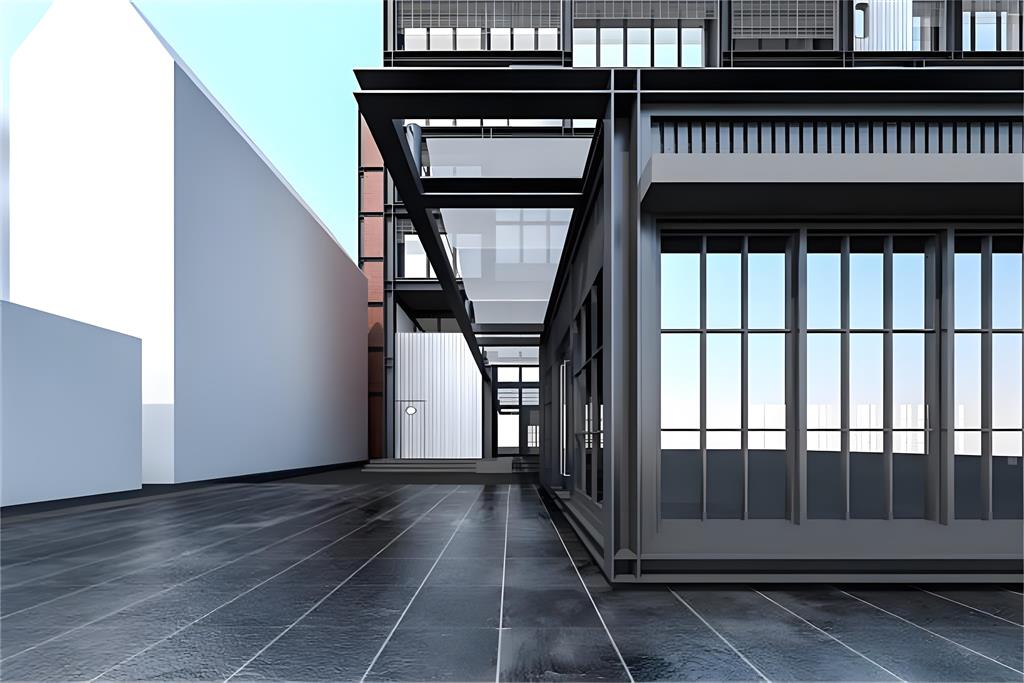

Curtain Walls

One of the most prominent applications is in curtain walls. These non - structural outer coverings of buildings are crucial for protecting the interior from external elements while also providing a modern and aesthetically pleasing look. Aluinno Aluminum Profiles are an ideal choice for curtain walls due to their lightweight nature and their ability to support large glass panels. This combination allows for the creation of sleek and contemporary facades that are not only visually striking but also energy - efficient. In many high - rise commercial buildings in urban centers, Aluinno Aluminum Profiles in curtain walls have become a signature feature, contributing to the unique identity of these structures.

The design possibilities with Aluinno Aluminum Profiles in curtain walls are vast. Architects can choose from a variety of profile shapes and sizes to create different patterns and textures on the building's exterior. Additionally, the ability to customize the surface treatment of the profiles allows for the creation of unique visual effects. For example, a mirrored surface treatment can be used to reflect the surrounding environment, creating a dynamic and modern look. In some high - end commercial buildings in major cities like New York and Hong Kong, curtain walls made of Aluinno Aluminum Profiles with custom - designed surface treatments have become iconic features, attracting both tenants and visitors alike.

Window Frames and Doors

Another important application is in window frames and doors. The strength and durability of Aluinno Aluminum Profiles make them a top - notch choice for framing large windows and doors. In modern architecture, large windows are highly favored as they allow ample natural light to penetrate deep into the interior of buildings, creating a more pleasant and inviting environment. Moreover, Aluinno Aluminum Profiles are highly resistant to weathering, which means they can withstand the harsh elements such as rain, wind, and sunlight without deteriorating easily. Their low maintenance requirements also make them a cost - effective solution in the long run, reducing the overall lifecycle costs of buildings.

The use of Aluinno Aluminum Profiles in window frames and doors also offers excellent thermal insulation properties. This is especially important in urban areas where energy consumption for heating and cooling is a significant concern. By reducing heat transfer through the window and door frames, these profiles can contribute to lower energy bills for building occupants. In addition, the profiles can be designed with integrated seals and gaskets to further enhance their insulation performance. Whether it's in residential or commercial buildings, these profiles are increasingly being used for window and door frames.

Roofing and Cladding

Aluinno Aluminum Profiles also find extensive use in roofing and cladding. Their corrosion resistance is a significant advantage, especially in areas with high humidity or industrial pollution. By using these profiles in roofing, the reflectivity property helps to reduce heat absorption, thereby enhancing the energy efficiency of buildings. In industrial buildings, for example, this can lead to substantial savings in cooling costs. In terms of cladding, the profiles provide an outer layer that not only safeguards the building from external damage but also adds to its visual appeal.

The use of Aluinno Aluminum Profiles in roofing can also contribute to the overall sustainability of the building. For instance, in green building projects, where environmental impact is a major consideration, the recyclability of aluminum and its ability to reduce energy consumption make it an ideal roofing material. Different surface treatments can be applied to the profiles to match the overall aesthetic of the building, whether it's a modern, minimalist look or a more traditional style. In some urban renewal projects, where old buildings are being renovated, Aluinno Aluminum Profiles are used for cladding to give the buildings a fresh and contemporary appearance while also improving their durability.

The following table further elaborates on the key applications of aluminum profiles in construction:

| Application | Advantages | Specific Examples |

| Curtain Walls | Lightweight, support large glass panels, create modern facades, energy - efficient | Facades of many high - rise commercial buildings in urban centers like Shanghai Tower in China, where the curtain walls made of Aluminum Profiles enhance the building's appearance and energy performance. |

| Window Frames and Doors | Strength, durability, weather resistance, low maintenance, allow natural light penetration, thermal insulation | Windows in modern residential complexes such as those in Singapore, where large aluminum - framed windows are a common feature, providing a bright and airy living environment. |

| Roofing and Cladding | Corrosion resistance, reflectivity, energy efficiency, protection and aesthetic appeal | Roofs of industrial buildings in areas with high pollution levels, like some parts of India, where Aluminum Profiles protect the building and reduce heat absorption; and the cladding on modern art galleries in Europe to give a sleek and contemporary look. |

The Sustainability of Aluinno Aluminum Profiles in Urban Development

Sustainability has become a cornerstone of modern urban development, and Aluinno Aluminum Profiles are in perfect alignment with this concept.

The recyclability of aluminum is one of the most remarkable features of aluminum profiles. Unlike many other building materials, aluminum can be recycled indefinitely without losing its essential properties. In fact, the process of recycling aluminum requires only about 5% of the energy needed to produce primary aluminum from bauxite ore. This implies that the use of Aluinno Aluminum Profiles in construction today can significantly reduce the demand for new raw materials in the future. When these profiles are recycled, they can be reused in subsequent construction projects, thereby minimizing the environmental impact associated with the extraction and processing of new aluminum.

Furthermore, the lightweight nature of aluminum profiles also contributes to their sustainability. In large - scale urban construction projects, where vast quantities of building materials need to be transported over long distances, the lightweight property reduces transportation emissions. This is because lighter materials require less energy for transportation, which in turn helps to lower the overall carbon footprint of the construction project. Additionally, the cost of transportation is also reduced, making aluminum profiles an economically viable option from a sustainability perspective.

Many aluminum profiles are made from recycled materials, which further enhances their sustainability credentials. This not only reduces waste but also promotes the circular economy concept within the construction industry. By choosing aluminum profiles, urban developers are making a conscious choice towards a more sustainable future for their cities.

In addition to these, the long lifespan of aluminum profiles also plays a role in sustainability. A longer - lasting building material means fewer replacements over time, which reduces the overall environmental impact associated with the production and disposal of building materials. This is especially important in urban areas where the scale of construction is large and continuous.

Aluminum Profiles’Role in Modern Infrastructure

Beyond the realm of buildings, Aluminum Profiles play a vital role in modern urban infrastructure.

Transportation Systems

In transportation systems, these profiles are widely used in various modes of transport. In trains, especially high - speed trains, the lightweight nature of aluminum profiles helps to reduce the overall weight of the train. This reduction in weight is crucial for achieving higher speeds and better fuel efficiency. For example, in many high - speed rail projects around the world, such as those in Europe and Asia, aluminum profiles are used in the body construction of the trains.

The use of aluminum profiles in trains also offers other advantages. They can be designed to have excellent crashworthiness, which is important for passenger safety. Additionally, their corrosion resistance ensures that the train's body remains in good condition over time, reducing maintenance costs. In buses and bicycles, the use of these profiles contributes to energy savings. In urban buses, lighter construction means less energy consumption during operation, which is beneficial for reducing emissions in congested city environments. Bicycles made with Aluinno Aluminum Profiles are not only lightweight but also durable, making them a popular choice for urban commuters.

Bridge Construction

In bridge construction, the strength and corrosion resistance of aluminum profiles are highly valued. Long - span bridges, in particular, require materials that can withstand the forces of nature and heavy traffic loads over extended periods. Aluminum profiles are less prone to rust and other forms of deterioration compared to traditional steel materials. This means that bridges constructed with aluminum profiles have a longer lifespan and require less frequent maintenance.

In addition to the above, the use of aluminum profiles in bridge construction can also lead to cost savings in the long run. Although the initial cost of aluminum may be higher than some other materials, the reduced maintenance requirements and longer lifespan can offset this. In regions with harsh environmental conditions, such as coastal areas or areas with high levels of industrial pollution, the use of these profiles can significantly enhance the durability of bridges. For instance, in some coastal bridge projects in the United States, aluminum profiles have been successfully used to reduce the maintenance costs associated with corrosion.

Public Amenities

Aluminum profiles are also increasingly being used in the development of public amenities. In street furniture, such as benches, waste bins, and bus shelters, the durability and low maintenance requirements of these profiles are ideal. They can withstand the wear and tear of public use and the elements without losing their functionality or appearance.

The use of aluminum profiles in public amenities also allows for greater design flexibility. For example, benches can be designed in unique shapes and colors to blend in with the surrounding urban environment or to make a statement. Lighting poles made from aluminum profiles are not only strong but also resistant to corrosion, ensuring reliable lighting in urban areas. Signage made with these profiles is also popular due to its long - lasting nature and the ability to be customized to different shapes and sizes. These applications contribute to the overall functionality and aesthetic quality of public spaces in cities.

Challenges and Future Prospects

Despite their numerous advantages, Aluminum Profiles in urban construction face certain challenges.

One of the primary concerns is the initial cost. Compared to some other building materials, such as steel or concrete, the cost of aluminum profiles can be relatively higher. However, it is important to note that this higher upfront cost is often offset by their long - term benefits. For example, their low maintenance requirements and longer lifespan can result in significant cost savings over the entire lifecycle of a building or infrastructure project.

The supply chain for aluminum profiles can also be a challenge. Fluctuations in global markets and geopolitical factors can affect the availability and cost of raw materials, as well as the transportation and distribution of the finished profiles. Ensuring a stable and sustainable supply of these profiles is crucial for maintaining their role in urban construction, especially as the demand continues to rise.

Another challenge is the perception among some builders and developers. Some may be more accustomed to using traditional building materials and may be hesitant to switch to aluminum profiles due to lack of familiarity. This requires more education and promotion of the benefits of these profiles in the construction industry.

Looking ahead, the future of aluminum profiles in urbanization appears highly promising. Advances in alloy technology are expected to further enhance the properties of these profiles. New alloy compositions may offer even greater strength, durability, and corrosion resistance, making them more suitable for a wider range of applications. Moreover, improvements in manufacturing processes are likely to make aluminum profiles more cost - effective.

As cities become more focused on sustainability, the demand for materials like aluminum profiles that offer both environmental and economic benefits is likely to increase. This trend is expected to drive further innovation and development in the aluminum profile industry, leading to more efficient and sustainable use of these profiles in urban construction. For example, new surface treatment techniques may be developed to further enhance the performance and aesthetics of the profiles.

Conclusion

In conclusion, Aluminum Profiles are an indispensable component in the context of global urbanization. Their unique combination of properties, including lightweight, strength, recyclability, and the ability to be customized through various manufacturing processes, meets the diverse requirements of modern urban construction while also supporting sustainable development goals.

As cities continue to grow and evolve, these profiles will undoubtedly play a crucial role in building the infrastructure necessary to accommodate the expanding urban populations. Whether it's in the construction of high - rise buildings, the development of transportation systems, or the creation of public amenities, Aluminum profiles will remain a key material in the future of urban development. Their role in promoting sustainable urban development cannot be overstated, and as the industry continues to innovate, we can expect to see even more applications and benefits from these remarkable profiles.

En

En

Location:

Location: