what is the most common aluminum profile

Outline

Introduction: Highlight the significance of aluminum profiles in modern industries and introduce Aluinno's role.

Definition and Production: Define aluminum profile, explain the extrusion process (heating billets, using dies), and emphasize its advantages like creating complex shapes and ensuring accuracy.

Industry Applications: Detail their uses in construction (windows, curtain walls), automotive (body frames, trims), aerospace (aircraft frames), industrial (machinery), and marine (boat hulls).

Conclusion: Summarize the importance of different aluminum profiles, restate Aluinno's commitment to providing solutions, and encourage readers to contact for assistance.

1. Introduction

In today's modern world, aluminum profiles have emerged as indispensable elements across a vast spectrum of industries. Their remarkable combination of lightweight construction, impressive strength, and outstanding corrosion resistance makes them the material of choice for countless applications. From the soaring skyscrapers that define our cityscapes to the sleek automobiles that zip along our roads, and from the intricate machinery that powers our factories to the advanced aircraft that traverse the skies, aluminum profiles are omnipresent, quietly enabling innovation and progress.

At Aluinno, we understand the pivotal role that aluminum profiles play in bringing your ideas to life. As a leading manufacturer and supplier in the field, we possess the expertise and experience to guide you through the diverse array of options available. Whether you're embarking on a large-scale construction project, seeking to enhance the performance of your industrial equipment, or aiming to add a touch of elegance to your architectural designs, our team is dedicated to helping you make informed decisions. In this blog post, we will embark on a journey to explore the most common aluminum profiles, delving into their unique characteristics, applications, and the value they bring. So, let's dive in and uncover the wonders of aluminum profiles together.

2. What is Aluminum Profile?

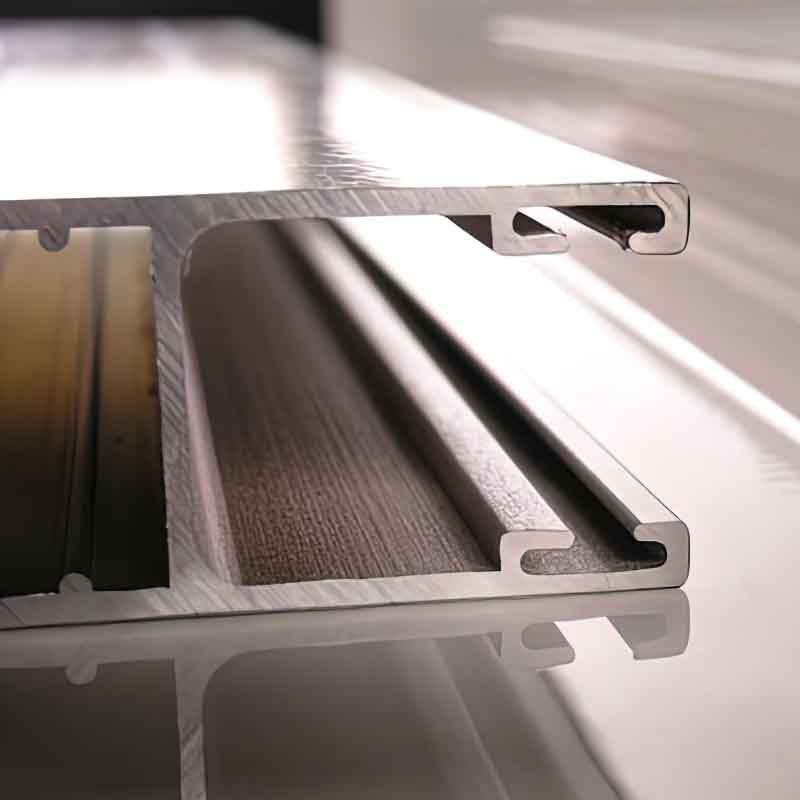

An aluminum profile refers to a long, narrow strip of aluminum alloy that has been extruded through a die to achieve a specific cross-sectional shape. These profiles are not just simple pieces of metal; they are the building blocks of modern design and construction. Composed primarily of aluminum alloy, which combines aluminum with other elements to enhance its properties, aluminum profiles offer a unique blend of strength, durability, and versatility.

The production process of aluminum profiles, known as extrusion, involves heating aluminum billets to a malleable state and then forcing them through a precisely designed die. This die imparts the desired shape to the aluminum, creating profiles with consistent dimensions and characteristics. The extrusion process allows for an incredible variety of shapes and sizes, ranging from basic geometric forms like squares, rectangles, and circles to highly specialized and complex configurations tailored to meet specific industry needs.

One of the most significant advantages of aluminum profiles is their lightweight nature. Aluminum has a relatively low density compared to many other metals, making it an ideal choice for applications where weight reduction is crucial. This characteristic is especially valuable in industries such as aerospace and automotive, where every ounce saved can translate to improved fuel efficiency and performance.

Despite their light weight, aluminum profiles do not compromise on strength. Thanks to advancements in alloy formulation and manufacturing techniques, they can exhibit remarkable tensile and compressive strength, capable of withstanding heavy loads and structural stresses. This strength-to-weight ratio makes them suitable for a wide range of structural and non-structural applications.

Corrosion resistance is another hallmark of aluminum profiles. When exposed to air, aluminum forms a thin, natural oxide layer on its surface, which acts as a protective barrier against further oxidation and corrosion. This inherent resistance to rust and degradation makes aluminum profiles highly durable, even in harsh environmental conditions, such as coastal areas with high salt content in the air or industrial settings where chemicals may be present.

These remarkable properties have led to the widespread use of aluminum profiles in numerous industries. In construction, they are used for window and door frames, curtain walls, roofing systems, and structural supports, providing both functionality and aesthetic appeal. In the automotive sector, aluminum profiles contribute to lighter vehicle bodies, improved fuel economy, and enhanced handling. The aerospace industry relies on them for aircraft frames, interior components, and wing structures, where weight savings are of utmost importance. Industrial machinery and equipment also benefit from aluminum profiles, which are used to build frames, conveyor systems, workstations, and enclosures due to their ease of assembly, customization options, and durability.

In summary, aluminum profiles are much more than just metal strips; they are the backbone of innovation and progress in multiple industries. Their unique combination of lightweight construction, high strength, and excellent corrosion resistance makes them an essential material for modern-day applications, enabling engineers, architects, and designers to bring their visions to life while meeting the demands of efficiency, durability, and performance.

3. The Extrusion Process of Aluminum Profile

3.1 How It Works

The extrusion process is at the heart of aluminum profile production, enabling the transformation of raw aluminum into the versatile shapes we rely on. It begins with carefully selected aluminum billets, which are heated to a precise temperature range, typically between 400°C and 500°C, depending on the alloy composition. This heating renders the aluminum malleable, ready to be shaped.

The heated billet is then loaded into the extrusion press, a powerful machine that applies tremendous force. As the press activates, a ram pushes the softened aluminum through a precisely engineered die. This die, often made of high-strength steel, features a cavity with the desired cross-sectional shape. The aluminum is forced to conform to the die's contours, emerging on the other side as a continuous profile with the exact shape dictated by the die.

One of the remarkable aspects of extrusion is its flexibility. Once extruded, the aluminum profile can be cut to any required length using specialized saws or shearing equipment. This means that whether you need a short section for a small component or a long length for a structural application, the extrusion process can accommodate your needs. For example, in the construction of a high-rise building, long aluminum profiles can be used for curtain walls, while shorter pieces can be cut for window frames and door surrounds.

3.2 Advantages of Extrusion

The extrusion process offers several distinct advantages that have contributed to the widespread use of aluminum profiles. Firstly, it allows for the creation of complex and intricate shapes that would be extremely difficult, if not impossible, to achieve through other manufacturing methods. From custom architectural details to specialized components in aerospace and automotive applications, extrusion can bring the most elaborate designs to life.

Secondly, extrusion ensures excellent dimensional accuracy and consistency. The tight control over the process parameters, such as temperature, pressure, and extrusion speed, results in profiles with precise cross-sectional dimensions and minimal variation along their length. This level of precision is crucial in industries where components must fit together precisely, such as in machinery assembly or electronics manufacturing.

Moreover, the extrusion process helps maintain the integrity of the aluminum's material properties. The rapid cooling that occurs as the profile exits the die helps to strengthen the material, enhancing its mechanical performance. Additionally, because extrusion is a continuous process, it is highly efficient for mass production, enabling manufacturers to meet the growing demands of various industries.

In conclusion, the extrusion process is a remarkable feat of engineering that unlocks the full potential of aluminum, making it possible to produce a vast array of profiles with consistent quality, complex geometries, and excellent performance characteristics. It is this process that forms the foundation for the diverse applications of aluminum profiles in our modern world.

4. Aluminum Profiles in Different Industries

4.1 Construction Industry

In the construction realm, aluminum profiles are ubiquitous, serving as essential elements in a wide array of applications. One of the most prominent uses is in window and door frames. Aluminum's natural resistance to corrosion makes it an ideal choice for these components, which are constantly exposed to the elements. Whether it's the driving rain, harsh sunlight, or fluctuating temperatures, aluminum frames can withstand the test of time without rusting or deteriorating. This durability not only ensures the longevity of the windows and doors but also reduces maintenance costs over the years.

Moreover, aluminum's lightweight nature simplifies installation, reducing the need for heavy lifting equipment and making the construction process more efficient. Architects and builders can design larger window openings and doors without compromising the structural integrity of the building, allowing for more natural light to flood interior spaces and enhancing the overall aesthetic appeal.

Aluminum profiles also play a crucial role in curtain walls. These non-structural, outer coverings of modern buildings are designed to provide insulation, weatherproofing, and an eye-catching facade. Aluminum curtain wall profiles are engineered to be strong yet lightweight, enabling the construction of towering skyscrapers with sleek, contemporary designs. The modular nature of these profiles allows for easy installation and customization, accommodating different architectural visions and building geometries.

Roofing and structural supports are other areas where aluminum profiles shine. In residential and commercial construction, aluminum's high strength-to-weight ratio makes it a preferred material for beams, columns, and roofing systems. It can span longer distances without the need for excessive reinforcement, reducing material costs and construction time. Additionally, aluminum's recyclability aligns with sustainable building practices, making it an environmentally friendly choice for the construction industry.

4.2 Automotive Industry

The automotive sector has witnessed a significant shift towards aluminum profiles in recent decades, driven by the pursuit of greater fuel efficiency and reduced vehicle weight. Aluminum body frames have become increasingly common, replacing traditional steel frames in many cars, trucks, and SUVs. By using aluminum, automakers can shave off hundreds of pounds from a vehicle's weight, leading to improved fuel economy and reduced emissions. This not only benefits the environment but also translates to cost savings for consumers at the gas pump.

In addition to body frames, aluminum profiles are extensively used for trims and exterior components. Bumpers, side skirts, and window surrounds made from aluminum offer enhanced durability and resistance to corrosion, even in harsh weather conditions. These components maintain their sleek appearance over time, enhancing the vehicle's resale value.

Lightweight engine components are another area where aluminum profiles make a significant impact. Cylinder heads, intake manifolds, and engine blocks fabricated from aluminum alloys help reduce the overall weight of the engine, improving performance and responsiveness. The improved heat dissipation properties of aluminum also contribute to better engine cooling, ensuring optimal operating temperatures and increasing the engine's lifespan.

4.3 Aerospace Industry

In the aerospace industry, where every ounce matters, aluminum profiles are indispensable. Aircraft frames demand materials that are not only lightweight but also possess exceptional strength and rigidity. Extruded aluminum profiles meet these requirements, providing the structural backbone for modern aircraft. From the fuselage to the wings and tail sections, aluminum is used extensively to reduce weight while maintaining the necessary structural integrity to withstand the extreme forces experienced during flight.

Interior structures, such as seating frames, overhead storage bins, and cabin partitions, also rely on aluminum profiles. These components need to be lightweight to minimize the overall weight of the aircraft, yet strong enough to support the loads imposed by passengers and cargo. Aluminum's versatility allows for the creation of complex shapes and designs that optimize space utilization and passenger comfort.

Wing components, including spars and ribs, are critical for flight safety and performance. Aluminum's high strength-to-weight ratio makes it the material of choice for these load-bearing elements. The wings must support the aircraft's weight during takeoff, landing, and in-flight maneuvers, while also minimizing drag. Aluminum profiles enable the design of efficient, aerodynamic wing structures that contribute to fuel efficiency and overall flight performance.

4.4 Industrial Applications

Industrial machinery and manufacturing processes benefit greatly from the versatility of aluminum profiles. In factories and production facilities, aluminum profiles are used to construct modular systems, conveyor frameworks, and machine enclosures. Their ease of assembly and customization options allow engineers to design and build custom machinery structures quickly and efficiently.

Frames and support systems made from aluminum profiles provide a lightweight yet durable foundation for industrial equipment. Workstations, assembly lines, and robotic arms can be built using aluminum profiles, reducing the overall weight of the machinery and making it easier to move and reconfigure as production needs change.

Conveyor systems, a vital part of many manufacturing processes, often rely on T-slot aluminum profiles. These modular profiles can be easily assembled and disassembled without welding, allowing for rapid modifications and adjustments to the conveyor layout. Whether it's a simple belt conveyor or a complex automated sorting system, aluminum profiles offer the flexibility and strength required to keep production lines running smoothly.

4.5 Marine Industry

Given the harsh and corrosive nature of the marine environment, aluminum profiles have emerged as the go-to material for many marine applications. Boat hulls and decks constructed from aluminum offer a winning combination of lightweight construction and excellent corrosion resistance. This not only improves the speed and fuel efficiency of the vessel but also ensures its durability in saltwater conditions. Aluminum hulls are less prone to rust and degradation compared to traditional steel or fiberglass alternatives, reducing maintenance requirements and extending the boat's service life.

Docks and piers also benefit from aluminum's properties. These structures are constantly exposed to water, waves, and salt spray, making corrosion a significant concern. Aluminum profiles can withstand these harsh conditions, providing a stable and long-lasting foundation for marine infrastructure. Whether it's a small fishing dock or a large commercial pier, aluminum's strength and resistance to corrosion make it a reliable choice.

In summary, aluminum profiles have found their way into virtually every major industry, each leveraging their unique properties to enhance performance, efficiency, and durability. From the buildings we live and work in to the vehicles we drive and the aircraft we travel on, aluminum profiles continue to shape the modern world.

5 Conclusion

In conclusion, the world of aluminum profiles is as diverse as it is fascinating. From the common yet essential standard profiles that form the backbone of countless everyday structures to the highly specialized custom and modular profiles that drive innovation in advanced industries, each type serves a unique purpose. We have explored how aluminum profiles, with their remarkable combination of lightweight design, strength, and corrosion resistance, have become integral to construction, automotive, aerospace, industrial, and marine applications.

At Aluinno, we are committed to being your trusted partner in harnessing the potential of aluminum profiles. Our extensive range of standard and custom solutions, backed by our dedication to quality and expertise in customization, ensures that we can meet the demands of any project, no matter how complex or specific. Whether you are embarking on a new construction venture, upgrading industrial machinery, or seeking to enhance the performance of your products, our team is here to guide you every step of the way.

If you have any questions, need expert advice, or are ready to explore the possibilities of aluminum profiles for your next project, don't hesitate to reach out to us. You can contact Aluinno at [insert contact details or link to contact page]. We look forward to collaborating with you and helping you turn your ideas into reality with the power of aluminum profiles. Thank you for joining us on this journey through the world of aluminum profiles, and we hope to hear from you soon.

En

En

Location:

Location: